Data-Driven Decision Making & AirMed

Data-driven decision-making is the practice of using facts, metrics, and data to guide strategic business decisions.

From optimizing cultivation processes to enhancing marketing strategies, the ability to analyze and act on data can make the difference between thriving and struggling in this dynamic cannabis space. By leveraging data, cannabis operators can gain actionable insights, reduce costs, improve yields, ensure compliance, and ultimately achieve a competitive edge.

Benefits of Data-driven Decision Making

Cannabis cultivation is a complex process influenced by numerous variables. By using data analytics, producers can monitor these variables in real-time, identify trends, and make adjustments to maximize yield and quality.

Cannabis is a resource-intensive product. Data-driven strategies help identify inefficiencies and optimize resource allocation. This ensures that resources are used as effectively as possible and reduces waste. These measures not only decrease operational expenses but also support sustainability initiatives—an important consideration for environmentally conscious consumers.

Compliance requires meticulous record-keeping and traceability throughout the supply chain. Data-driven systems that leverage information to demonstrate adherence to quality and safety standards enhance credibility with regulators and customers alike. Moreover, predictive analytics can help identify potential risks, enabling proactive measures to mitigate them.

As the cannabis industry matures, innovation is key to staying ahead of competitors. Data-driven insights can empower you to experiment with new cultivation techniques, product formulations, and market strategies. By staying informed and agile, you can seize opportunities and respond effectively to market shifts.

With narrow profit margins and significant operational costs, data-driven decision-making can also support financial sustainability. Data analytics can provide insights into cost drivers, helping you identify areas where they can reduce expenses or increase efficiency. Analyzing labor costs and production timelines might highlight opportunities to streamline operations, while inventory data can ensure that stock levels align with demand, reducing the risk of overproduction or stockouts.

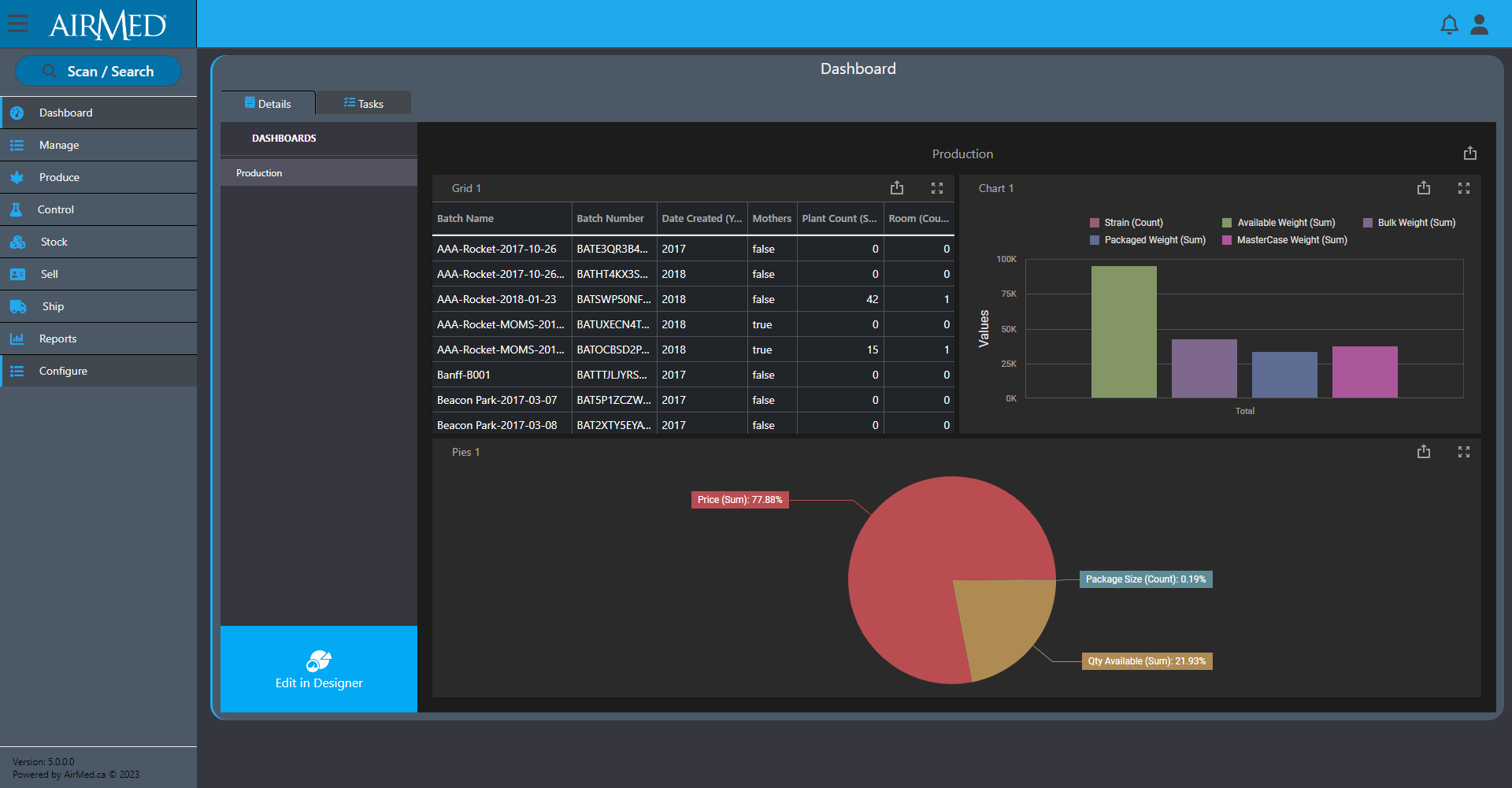

AirMed & Your Data

AirMed has always gone beyond other systems by tracking and reporting thousands of fields of data.

Dozens of reports come standard with AirMed, but we also offer an optional report designer to create unlimited custom reports with access to every field of data in the system. You can select individual fields to include in a report and add options to manage master-detail relationships, cross-tab reports, table and vertical reports, and filter options.

And our optional business intelligence (BI) designer provides pre-designed dashboard widgets that offer the best data visualization option for you. You can create insightful and information-rich decision support systems by simply selecting the appropriate UI widget: Chart, Pivot Table, Data Card, Gauge, TreeMap, Map, Grid, or simple Filter elements. By dropping data fields, results are immediate, accurate and always relevant.

For those who wish to edit or create new widgets, the BI Dashboard is engineered to let you spend more time on business and less on UI customization. Whether it’s manipulation of individual chart series, specifying a pivot table’s dimensions or connecting UI elements to fields across different data-sources or data providers, the BI Dashboard designer is built to make your experience a productive one.

Conclusion

Incorporating data-driven decision-making provides the ability to collect, analyze, and act on data to optimize processes, improve product quality, reduce costs, ensure compliance, and remain competitive. AirMed has been designed to help you embrace a data-driven approach.

For more information visit our Software page.

Report: Global Cannabis 2024-2028

The Global Cannabis Report: 5th Edition delivers a thorough analysis and insight into the world’s key cannabis markets, organised by region. This edition explores the global evolution of cannabis markets and examines possible future developments on the international stage. Additionally, it highlights the most notable and relevant trends in the industry, offering regional insights, market sizing data and analyses, and exclusive interviews with cannabis industry experts from around the world.

This report is produced by Prohibition Partners, which provides specialist information, data analytics and digital commerce solutions to the B2B cannabis industry.

For more information and to download the ‘Lite” version of the report for free, visit:

https://prohibitionpartners.com/reports/the-global-cannabis-report-5th-edition/

SPARK BC Conference: March 5, 2025 in Vancouver

SPARK 2025 is hosted by the Alliance of Beverage Licensees (ABLE BC), the voice of British Columbia’s bars, pubs, and private liquor and cannabis stores.

An electric convergence of industry leaders in cannabis and liquor retail make this event your chance to fuel innovation, share expertise, and drive growth in your operations.

Covering a wide range of topics including advocacy, community safety, staff retention, service excellence, growth, regulations, and more, this is your comprehensive resource for innovation and connection.

With carefully designed sessions and engaging speakers, SPARK 2025 will give you the tools to accelerate your business operations in the private liquor & cannabis industries.

Join ABLE BC on Wednesday, March 5, 2025, at the Sheraton Vancouver Wall Centre for BC’s premier liquor & cannabis conference.

For more information on the conference visit: https://www.bchotelandliquorconference.com/

For more information on the Alliance of Beverage Licensees, a non-profit organization funded by membership dues, our mission is to help your liquor or cannabis business succeed, visit: https://ablebc.ca/

10 Ways to Increase Cannabis Profits in 2025

High taxes, market saturation, and increased competition are cutting into profit margins for cannabis producers in Canada. In some areas, oversupply has driven prices down, affecting profitability for both growers and retailers.

With so many challenges complicating efforts for legitimate businesses to thrive, what can cannabis producers do to increase profits? We’ve compiled 10 strategies to help you cultivate success in the upcoming new year.

1. Diversify Product Selection: Broadening your offerings to include edibles, topicals, oils, and tinctures can create a wider customer base.

2. Target Niche Markets: Focusing on specific demographics or consumer needs, such as organic or medical cannabis, can establish a unique selling proposition.

3. Expand Distribution Channels: Export markets can offer new channels for Canadian cannabis, but be aware that meeting compliance in other regions can be costly. There are, however, alternatives. Selling to GMP-compliant organizations is one. Another is boosting your reach in Canada by partnering with retailers or large distributors and by selling online through direct delivery programmes.

4. Educate Consumers: Providing educational materials about product benefits and applications can strengthen customer engagement and drive sales.

5. Enhance Quality Control: Establishing high-quality cultivation practices can lead to superior products allowing for premium pricing and inspiring customer loyalty.

6. Optimize Processes: Creating formulas for cultivation or manufacturing by developing repeatable plans, templates, and recipes can ensure success again and again and trim waste.

7. Operate Efficiently: Streamlining through automation, standard operating procedures and improved resource management can reduce costs and increase output.

8. Minimize Risks: Active prevention through workforce management, approval workflows, and incident tracking lowers expenditures resulting from errors and damages.

9. Systemize Compliance: Having a system in place to administer compliance and stay ahead of regulatory changes can protect profits.

10. Improve Decision Making: Utilizing business intelligence and data analytics to track operations and consumer trends can help you make better decisions toward future success.

By implementing these strategies, cannabis producers can position themselves for greater financial success in a competitive market.

For information on the many ways AirMed can help you improve profitability, click the Request Demo button at the top of the page and a team member will be in touch. In the meantime, visit our Software page.

International Medical Cannabis Conference: Feb 13-14, 2025 in Bern Switzerland

IMCCB-25 aspires to bring together a diverse assembly of leading researchers, clinicians, industry professionals, and other experts and opinion leaders from around the world.

The conference will cover a broad spectrum of topics, including basic and clinical methodologies, safety, analytics, pharmaceutics, regulatory and legal considerations, pharmacological insights, and technological advancements. Emphasis is on practical implications for patients, researchers, medical persons, and industry leaders alike. Additional topics include palliative care, women medicine, psychiatry and geriatric diseases, niche indications as well as non-medical cannabis use disorders.

IMCCB-25 seeks to inform participants about the latest evidence and concepts regarding cannabis- and cannabinoid-based therapies. It aims to assist prescribers in practically implementing best practices based on current research, expert opinions and therapy guidelines. Furthermore, the conference provides a unique platform for the exchange of ideas and practices in medical cannabis among professionals and patients, fostering innovative and engaging discussions.

IMCCB-25 will be held February 13-14, 2025 at the University of Bern, Switzerland. For more information visit: https://www.imccb.org/

Cannabis Industry Forecast for 2025

What’s in the cards for cannabis in 2025? We’ve rounded up some of the predictions.

A report from insurance brokerage Hub International states that “In a volatile marketplace, risk mitigation will separate success from failure.” The document contains results from HUB’s Executive Outlook Survey, which polled 900 C-Suite and VP-level executives on the issues facing them on profitability, employee vitality and organizational resilience. “Outlook 2025 Cannabis” discloses that 80% of Canadian cannabis companies identified rising costs as the biggest challenge to profitability, but only 65% feel prepared to address it. https://www.hubinternational.com/en-CA/insights/outlook/2025/cannabis/

BNN Bloomberg posted a video titled, “Challenges in Canada’s Cannabis Sector,” featuring an interview with Ben Kaplan, author of Catch A Fire: The Blaze and Bust of the Canadian Cannabis Industry. Kaplan, a Brooklyn-born and Toronto-based writer and editor and the founder of KIND Magazine distributed in Canada’s legal weed shops, claims the industry is currently “right-sizing”. https://www.bnnbloomberg.ca/video/shows/the-open/2024/12/24/challenges-in-canadas-cannabis-sector/

Ben Kaplan also penned an opinion piece for the Globe & Mail titled, “Forgotten in the cannabis crash is how the industry is a Canadian success story.” https://www.theglobeandmail.com/business/commentary/article-forgotten-in-the-cannabis-crash-is-how-the-industry-is-a-canadian/

Investing News Network published “Cannabis Market Forecast: Top Trends That Will Affect Cannabis in 2025.” While mostly focused on the U.S. market, the article mentions Canada. Overall, INN predicts that “2025 could be a year of transformation for the cannabis industry.” https://investingnews.com/cannabis-forecast/

For general and breaking news on the Canadian cannabis industry, visit one of the sites below.

Cannabis in Canada Review for 2024

There’s something about the end of one year and the beginning of another that makes people want to look back as they leap forward. End-of-year recaps are common in the news. But when we looked, we found many covering the U.S. cannabis industry and the process of decriminalization. But there were almost none about Canada. So we turned to ChatGPT, a type of artificial intelligence trained on large amounts of text data that uses an algorithm called a transformer to generate text. After scouring the Internet, ChatGPT came up with the following key developments for the Canadian cannabis industry in 2024.

Maturing Legal Market

The legal cannabis industry in Canada is entering its fifth year since the nationwide legalization in 2018. While the initial enthusiasm has settled, the market is now focusing on consolidation, innovation, and consumer education. Cannabis sales remain strong, but growth rates have slowed compared to the initial years. There is now a greater emphasis on quality and differentiation rather than simply expanding the market.

Industry Challenges

Despite initial optimism, the cannabis industry faces significant challenges:

- Profitability Issues: Many cannabis companies continue to struggle with profitability due to oversupply, high taxation, and competition from the illegal market. Prices have come down, but not always enough to outcompete illicit operators.

- Regulatory Hurdles: Companies are still navigating complex regulations, particularly around packaging, labeling, and marketing. The government has been slow to adjust some of these regulations to allow for more dynamic industry growth, such as expanding retail hours or reducing restrictive rules for cannabis advertising.

- High Taxes and Licensing Fees: The federal and provincial governments have kept taxes high on cannabis, which has affected margins for producers and retailers.

Expanding Product Offerings

In 2024, cannabis companies have expanded their product offerings, with a continued shift towards innovative products beyond dried flower, including:

- Edibles and Beverages: Cannabis-infused beverages and edibles have gained significant traction, providing a more discreet and enjoyable consumption method. These products are now a larger portion of the legal cannabis market.

- Vapes and Concentrates: Vaping continues to be popular among cannabis consumers, though it faces some regulatory scrutiny due to health concerns. Concentrates, like hash and distillates, are also on the rise.

- Medical Cannabis: Medical cannabis is still a crucial market, with more people accessing it for health-related reasons. New research and trials have also driven more interest in medical products, particularly those with a focus on CBD.

Consumer Trends

Consumer preferences have become more sophisticated. In 2024, Canadian cannabis consumers are looking for quality, consistency, and variety. This includes an increased demand for:

- Sustainable and Organic Products: Consumers are increasingly seeking environmentally friendly cannabis options, pushing producers to adopt sustainable farming practices.

- Microdosing: With more people seeking subtle, controlled experiences, microdosing has become a prominent trend, especially in edibles and tinctures.

- Brand Loyalty: As the market matures, consumer brand loyalty is becoming more pronounced, with established companies gaining recognition for their quality and reliability.

Legal Developments

The Canadian government continues to tweak the legal framework around cannabis in 2024. Several provinces are exploring the possibility of relaxing some restrictions:

- Expansion of Retail Stores: While Ontario leads in retail outlets, provinces like British Columbia and Alberta are increasing their number of licensed dispensaries, making cannabis more accessible to consumers.

- Home Cultivation Rules: Discussions around expanding personal cultivation rights are ongoing, with some provinces exploring allowing more plants to be grown for personal use, while others remain restrictive.

- International Market Opportunities: As Canada’s domestic market stabilizes, there’s growing attention on international markets for cannabis exports. Canadian companies are positioning themselves to benefit from the global cannabis boom, especially in Europe and emerging markets.

Social and Cultural Changes

Cannabis is now more ingrained in Canadian culture than ever. Public attitudes have become more accepting, especially regarding medical and wellness use. However, some societal issues remain:

- Concerns about Youth Access: Despite strict age restrictions, there are concerns about the accessibility of cannabis to minors, particularly through online sales or in neighborhoods with high retail density.

- Workplace Policies: As cannabis becomes more mainstream, workplaces are adapting to accommodate employees who consume cannabis. Employers are grappling with issues surrounding cannabis use, workplace safety, and testing.

The Black Market’s Continued Impact

The illicit cannabis market remains a significant challenge. Although legalization has greatly reduced illegal cannabis sales, the black market still exists, driven by lower prices, a wider selection of products, and a lack of trust in the legal system. Tackling the black market through regulation adjustments and lowering taxes is seen as a key area for future policy development.

Conclusion

Overall, the cannabis industry in Canada in 2024 is in a phase of refinement. While there are still challenges like profitability, regulatory barriers, and competition from the illicit market, the industry is maturing and diversifying its offerings. Consumer trends are shifting towards quality, sustainability, and innovation, while legal and regulatory adjustments are set to shape the market in the coming years. As Canada’s cannabis market continues to stabilize, the industry is positioning itself for long-term growth, both domestically and internationally.

Thanks ChatGPT! Content courtesy of https://chatgpt.com/.

If you are looking for media reviews of the cannabis industry that include some information on Canada, please click the links below:

https://www.reuters.com/legal/litigation/cannabis-2024-year-review-2024-11-13/

https://investingnews.com/daily/cannabis-investing/cannabis-market-update/

Happy New Year!

As we enter our second decade in business, we can’t help but look back on our industry’s history. Cannabis in Canada has certainly had its ups and downs, and we at AirMed have watched it from the inside, as have many of you. And as we welcome another new year, we do so with renewed commitment to Canada’s cannabis industry, to our partners and especially to our clients. May the New Year bring fresh insights, renewed energy, and exciting opportunities to you and to us.

We wish you a year filled with boundless opportunities, achievements and growth. Cheers to moving forward with positivity and purpose in 2025. From all of us at AirMed, Happy New Year!

Season’s Greetings to Our Clients & Partners

As we close out our first decade in business, we’d like to take this opportunity to thank all our clients and industry partners for their support. You’re the reason we strive for innovation & excellence, and we’re grateful for the trust you’ve placed in us. Our goal for the past 10 years has been to build strong, lasting relationships that benefit both your business and ours. Together we can achieve great things. We look forward to working with you in the coming year. Here’s to a joyous holiday season and a prosperous 2025!

All the best from the team at AirMed.

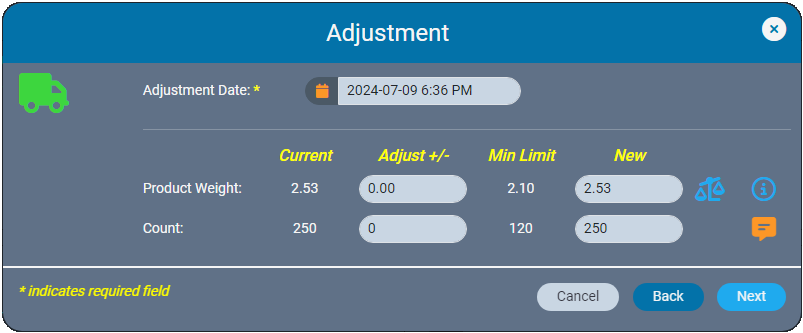

Inventory Ledgers: Adjustments & Corrections

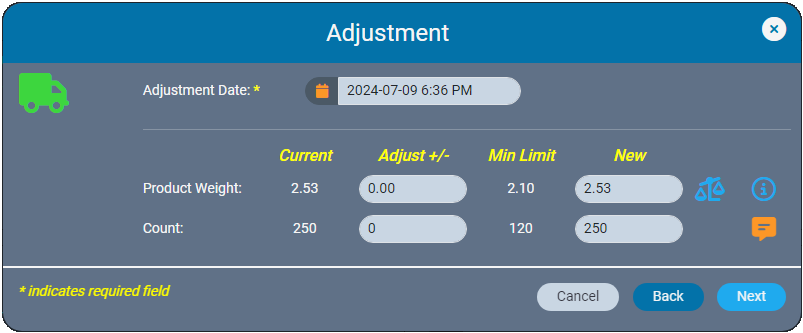

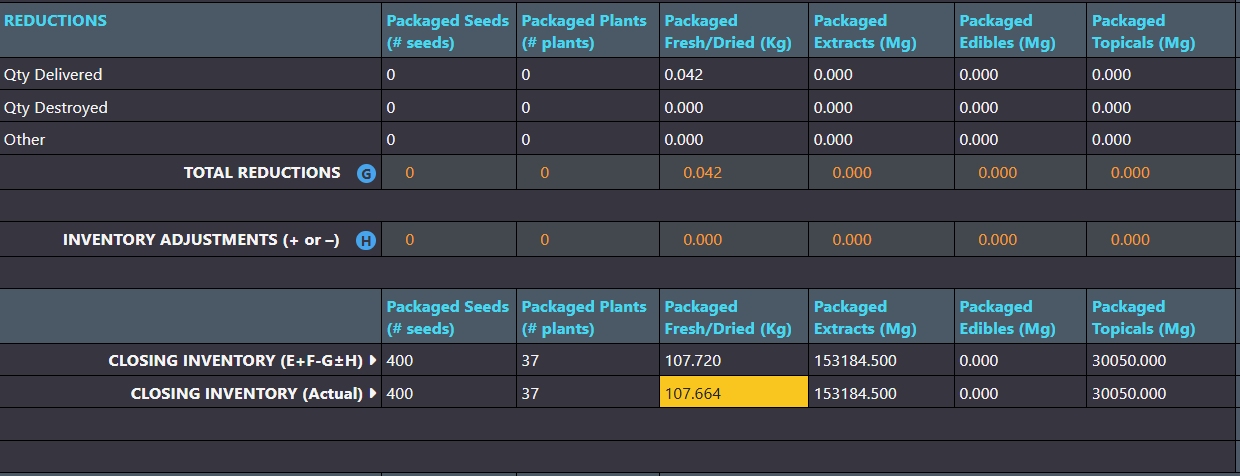

We recently announced the introduction of Inventory Ledgers in AirMed 5. This new functionality was designed to streamline your inventory management and recordkeeping. In this post we go into more details about the adjustments and corrections features in our inventory ledgers.

In the event of data entry errors, inventory ledgers make it easy to adjust weights and counts to resolve discrepancies. AirMed ensures that backdated adjustments are logically aligned with all prior and subsequent records. The ledger prevents negative balances by automatically validating that backdated weights or quantities are consistent with subsequent records.

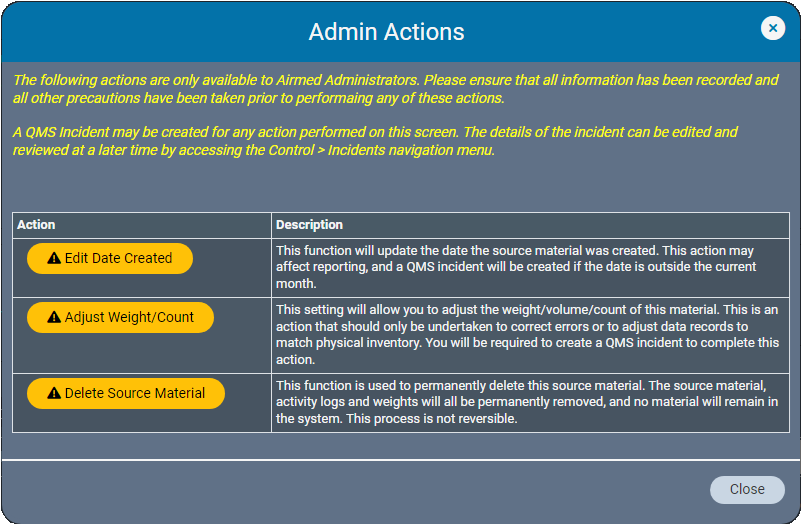

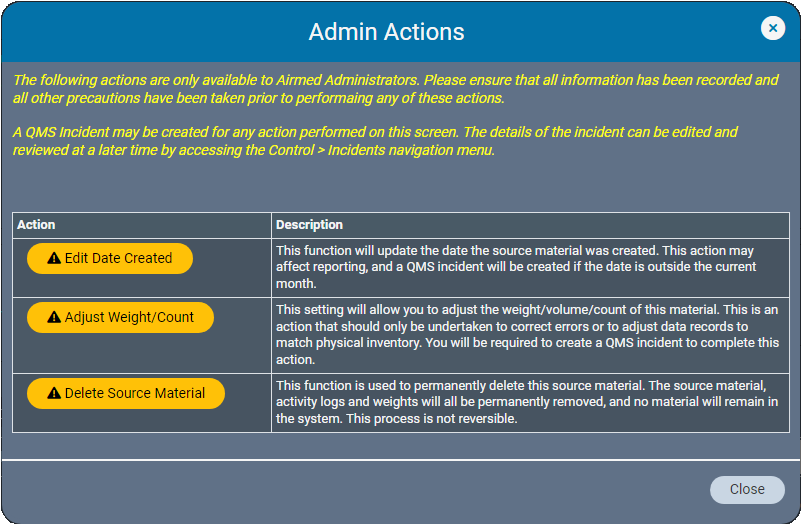

Whether you are making a correction immediately or at a later date, AirMed offers multiple correction tools. Previously found in the Actions Menu, these options are now located in the ‘Admin Actions’ section, visible only to users with supervisor-level access.

For example, if you create a new inventory item with an incorrect date, you can amend the creation date based on the date of the parent record. All changes are logged in both the affected item’s ledger and the parent record ledger.

Additionally, new options are available to delete incorrect records or merge materials back into their original source when appropriate.

Adjustments that affect inventory levels are clearly categorized in monthly compliance reports.

While mistakes are inevitable, you can leverage AirMed’s technology to get you back on track.

We designed our new inventory ledgers to empower you to correct errors and ensure that your records accurately reflect your physical inventory. For more information about AirMed 5 visit our Software page.

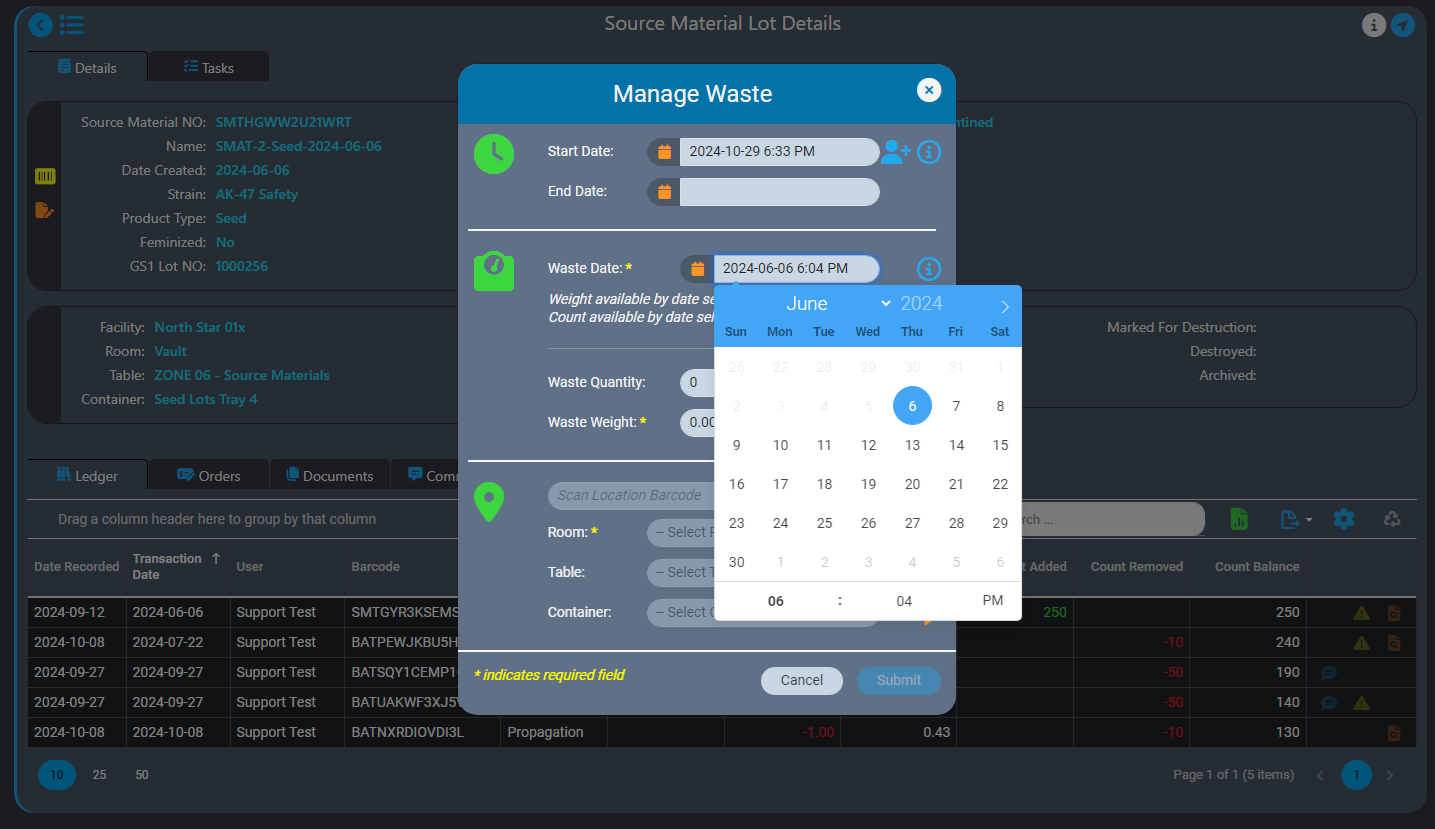

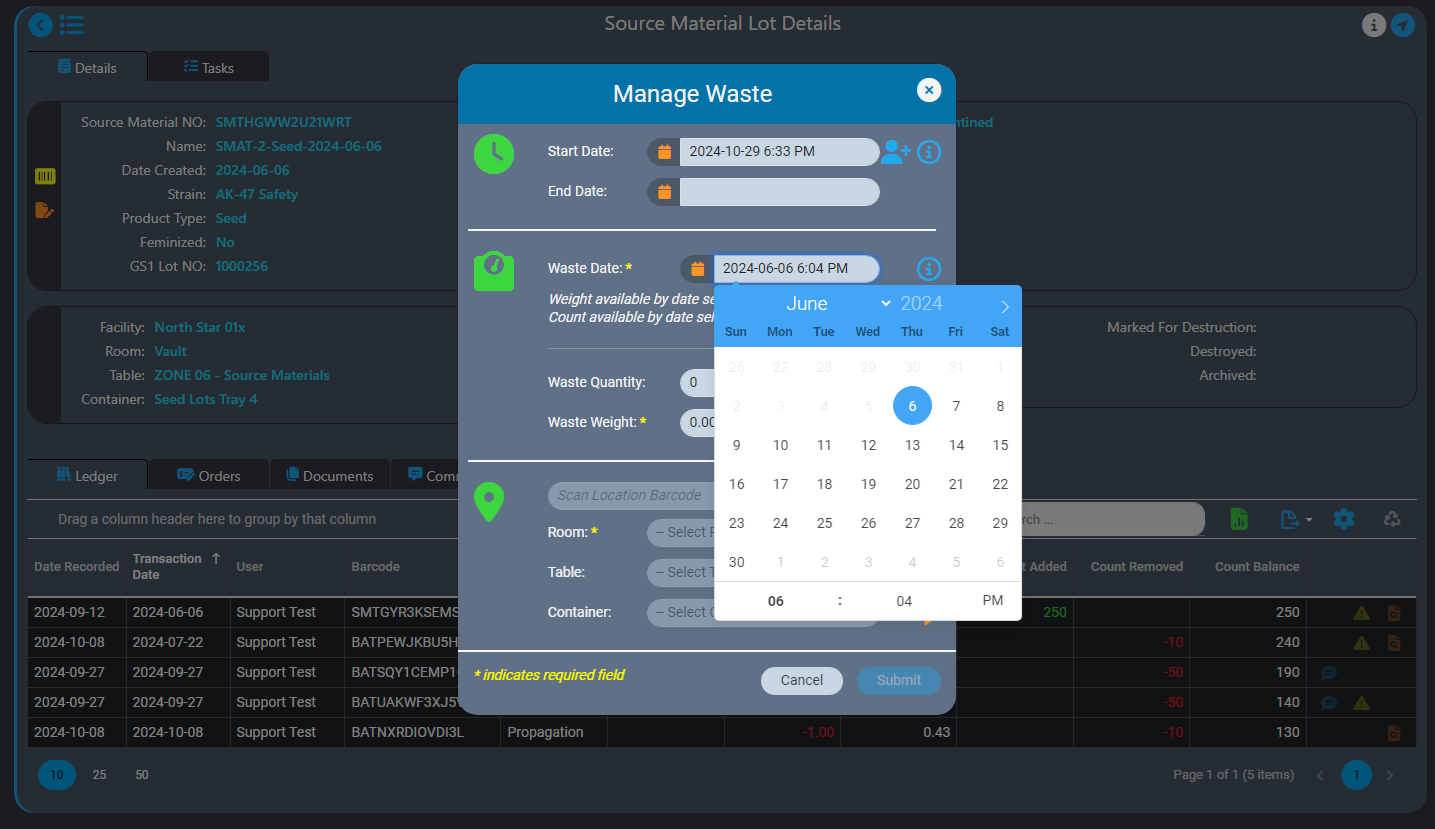

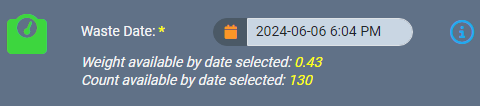

Inventory Ledgers: Intelligent Backdating

We recently announced the introduction of Inventory Ledgers in AirMed 5. In this post we go into more details about the intelligent backdating feature in our inventory ledgers.

Our intelligent record backdating ensures that any quantity or weight you enter will not lead to discrepancies in subsequent records. When backdating an adjustment, AirMed checks that it aligns logically with all successive records.

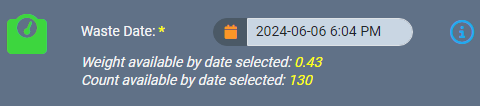

For instance, if you need to log waste for a source material, our safeguards won’t let you accidentally backdate a record to a date that is before the source material was created. You can only enter a date that is after the date the source material was created.

If an inventory item is created with the wrong date, admin tools can be used to adjust the creation date to match the creation of the parent record (e.g., adjusting a lot’s creation date to align with the date of the harvest). All changes are logged in both the affected item’s ledger and the parent record’s ledger.

If a backdated action impacts monthly compliance reporting, AirMed will automatically generate an incident within our built-in Quality Management System (QMS). Supervisors can then investigate and resolve the incident, document the findings, and track it through a severity assessment and impact evaluation.

Having an efficient way of tracking and resolving discrepancies not only helps you meet compliance but also saves you time and money.

Intelligent backdating lets you reconcile your data with your physical inventory while satisfying your regulatory obligations. For more information about AirMed 5 visit our Software page.

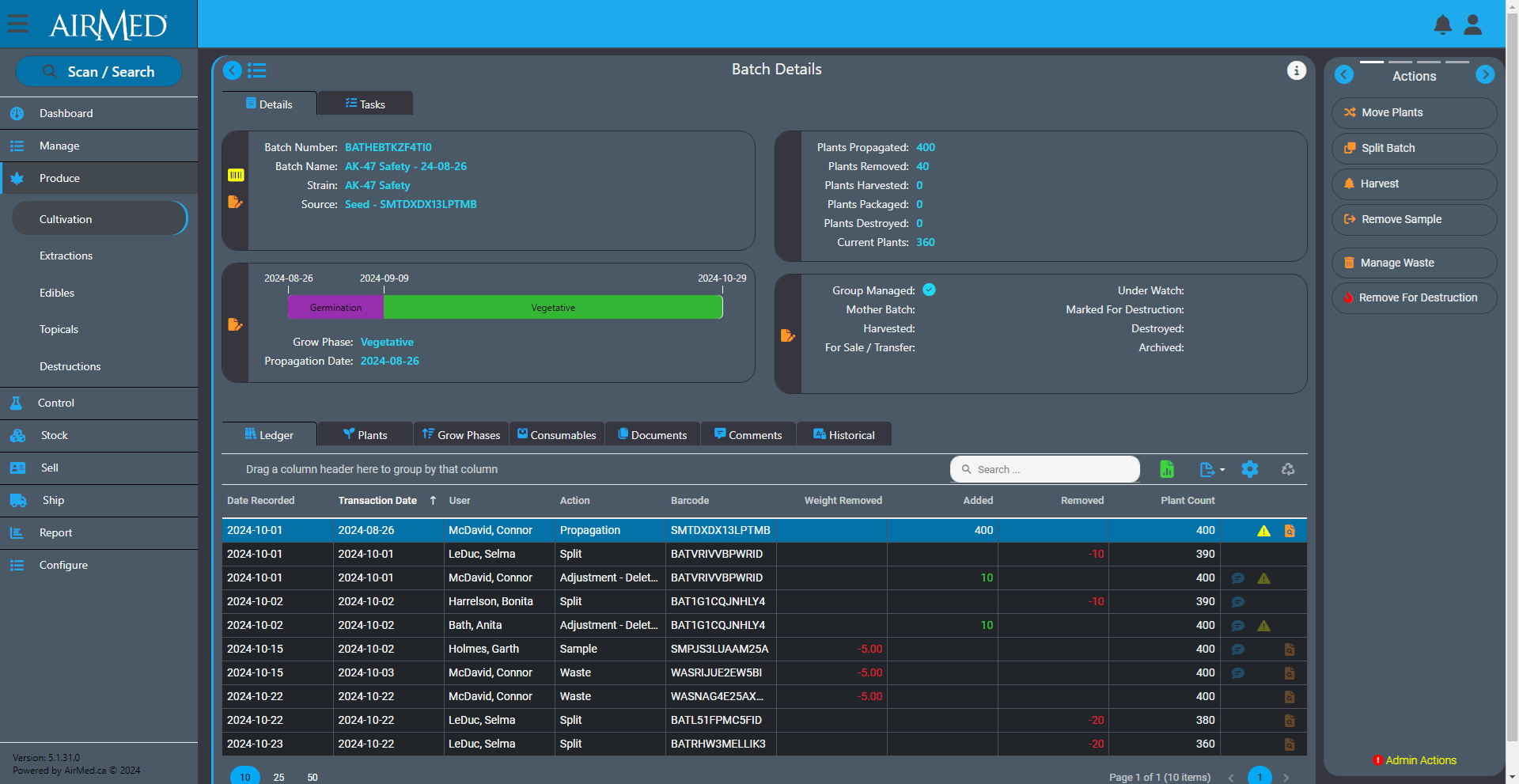

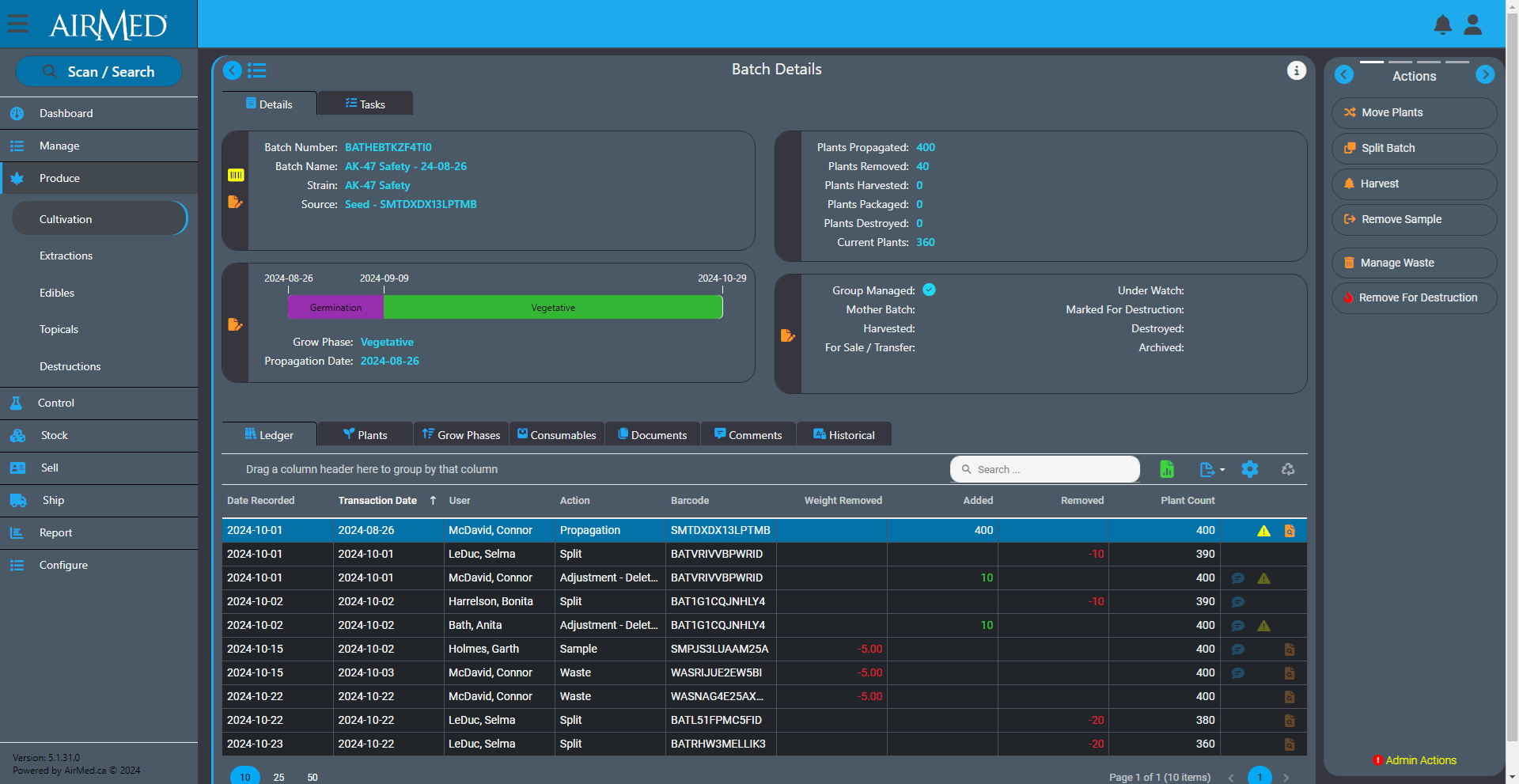

Inventory Ledgers: Tracking

We recently announced the introduction of Inventory Ledgers in AirMed 5. This new functionality was designed to streamline your inventory management and recordkeeping.

The ledger lets you track actions performed on an inventory item. These actions are referred to as transactions in the ledger. You use the ledger as a perpetual register that records each transaction for an inventory item.

To use the ledger for a batch, for example, open the Batch Details screen and look for the Ledger tab. The tab shows a table that you use to record individual transactions related to that batch.

Each row offers fields for the date that the transaction took place along with the date the transaction was recorded in case they are different. There are also fields for the type of action that occurred, the user who performed the action and weights or counts added or removed during the action. The final column provides icons to visibly indicate adjustments or corrections to the batch. You can re-order the columns in the table by dragging.

The benefits of inventory ledgers are seen in both operational efficiency and compliance. Not only do they let you monitor the progress of a batch or lot, but tracked actions can be used to create a template for future production. During an audit, the ledger serves as a detailed register about each item, which can be used to validate processes and verify physical inventory.

Our inventory ledgers are designed to help you optimize your operations and ultimately enhance profitability. For more information about AirMed 5 visit our Software page.

MJBizCon 2024: Dec 3-6 in Las Vegas

The 13th annual MJBizCon is taking place December 3-6 in Las Vegas. Billed as the ultimate hub where global cannabis executives come together, this event is for all industry members from cultivators and manufacturers to retailers and brands to the essential suppliers that serve the community.

“MJBizCon is where you FUEL YOUR FIRE. Ignite your passion, spark conversations, gain critical insights, and forge the business partnerships needed to achieve fire-status in the cannabis industry.”

This event hosted by MJBIz magazine will be held December 3 to 6, 2024 at the Las Vegas Convention Center. For more information visit: https://mjbizconference.com/

Report: Veterans and Cannabis Mental Health

The Mental Health Commission of Canada (MHCC) has published a report titled Closing Research Gaps on Cannabis and Mental Health – Veteran-Specific Findings.

Over the past five years, MHCC has led a research program to assess the impact of cannabis on the mental health of diverse populations. MHCC recent released the results of studies that explored the relationship between cannabis and mental health among Canadian veterans.

“According to these studies, Canadian Veterans are significantly impacted by a range of physical and mental health conditions, which medical cannabis is frequently used to manage.”

Key findings in this report include the following.

- Veterans use cannabis for many reasons and experience a range of benefits and harms.

- The relationship between cannabis use and trauma is unique and nuanced for veterans.

- Barriers to accessing medical cannabis persist after legalization.

- Stigma prevents many veterans from accessing formal health-care supports.

The Mental Health Commission of Canada is a national non-profit organization created by the Canadian government in 2007 in response to a senate committee tasked to study mental health, mental illness, and addiction.

To read the full report, visit:

https://mentalhealthcommission.ca/resource/cannabis-synthesis-report-veterans/

Business of Cannabis Summit 2024: Nov 26 in Berlin

Since 2017 Business of Cannabis has highlighted the companies, brands, people and trends driving the industry. The Berlin Executive Summit will connect, inspire, and empower top cannabis industry leaders from Germany and across Europe. Dive into groundbreaking discussions, innovative strategies, and forward-thinking practices that will shape the future of Germany’s dynamic cannabis market. Don’t miss this unparalleled opportunity to elevate your leadership, drive growth, and forge powerful partnerships in the ever-evolving German and wider European cannabis landscapes.

Topics at this event include:

- Cannabis Associations

- Commercial Opportunities

- Home Cultivation

- Pillar 2 & Future Outlook

- Medical Cannabis

- Market Dynamics & Consolidation

This in-person event is being held November 26 at the PALISA, Palisadenstraße 48, 10243 in Berlin, Germany.

For more information visit: https://www.cannabisberlin.live/

AirMed 5 Introduces Inventory Ledgers

AirMed 5 now features powerful new functionality to simplify inventory management and improve recordkeeping. With the integration of inventory ledgers throughout the system, you can effortlessly track all transactions related to your inventory.

Comprehensive Tracking

Inventory ledgers provide detailed tracking of every addition or reduction to inventory, whether in batches or lots. Each entry includes the user responsible for the transaction, along with the date, time, transaction type, and the corresponding weight or quantity. This ensures full visibility into the usage of each batch and lot, providing a clear audit trail. Additionally, clickable links enable quick access to related records and associated comments.

Intelligent Backdating

Intelligent record backdating ensures that adjustments or entries made in the past do not cause discrepancies in future records or reporting. For example, if waste for a source material needs to be logged, AirMed ensures that the waste entry can be backdated only after the source material was created. The ledger also prevents negative balances by automatically validating that backdated weights or quantities are consistent with subsequent records. If a backdated action impacts monthly compliance reporting, AirMed will automatically generate an incident within our built-in Quality Management System (QMS).

Efficient Adjustments & Corrections

Inventory ledgers make it easy to adjust weights and counts to resolve discrepancies. AirMed ensures that backdated adjustments are logically aligned with all prior and subsequent records. Adjustments that affect inventory levels are clearly categorized as ‘other additions’ or ‘other reductions’ in monthly compliance reports.

Error Correction Options

In the event of data entry errors, AirMed offers multiple correction tools. For example, if an inventory item is created with the wrong date, admin tools can be used to correct the creation date to match the creation of the parent record (e.g., adjusting a lot’s creation date to align with the date of the harvest). All changes are logged in both the affected item’s ledger and the parent record’s ledger. Additionally, new options are available to delete incorrect records or merge materials back into their original source when appropriate.

The benefits of our new inventory ledgers include more accurate tracking, improved operational efficiency and easier compliance. For more information about AirMed 5 visit our Software page.

MedTech World Summit 2024: Nov 6-8 in Malta

The MedTech World Summit, which is reported to incorporate Medical Cannabiz World, is designed to connect money with medtech and bills itself as 2024’s leading MedTech startup & investor summit.

More than 3,000 attendees are expected from diverse regions including the UK, Europe, North America, Asia, the Middle East, and North Africa. This event promises networking meetups, investment opportunities with top MedTech investors, and connections with startups.

During the three-day event, attendees can participate in various activities such as panel discussions, CEO-only workshops, technology showcases, exhibitions, networking sessions, pitch competitions, cultural activities, as well as MedTech Malta Awards Gala.

This in-person event is being held November 6 through 8, 2024 in Valletta, Malta. For more information visit: https://med-tech.world/

Production Orders in AirMed 5

Our new Production Orders features will offer the ability to synchronize AirMed more easily with external enterprise resource planning (ERP) systems such as NetSuite or Microsoft Business Central.

When combined with tasks and approvals, this provides a high level of automation and ensures that product that is created meets market demand.

Internal Production Orders

Production Orders are essentially a wrapper for activities related to producing material such as cannabis, extractions, packages, topicals, or edibles.

Internal Production Orders are used to plan for production over a specified period of time. For instance, if producers are involved in cultivation, they can create internal production orders to produce new batches, harvest and dry them, and produce bulk products for sale or for additional processing.

Once a production order is created, it can optionally cascade out all the tasks related to the item being produced, even if some of the production requires routing to external organizations and suppliers.

Internal production orders can be used to plan production for any period of time. Multiple internal production orders can cover an entire year for a producer.

External Production Orders

External production orders are based on a sale to another organization, such as a provincial government distribution warehouse. An external production order would typically be tied to a purchase order from an external organization.

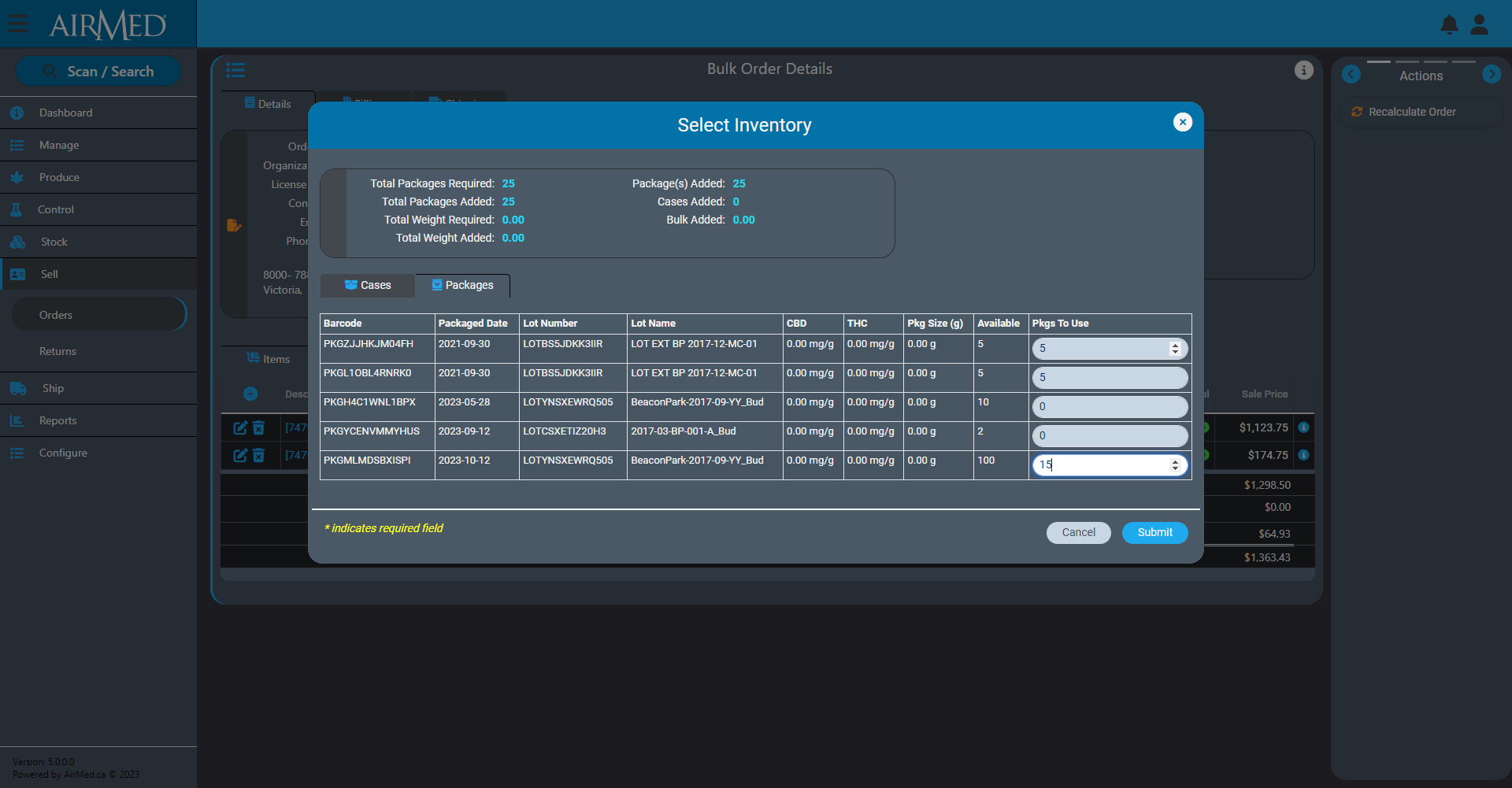

Using this feature, a producer will be able to see if there is existing inventory to fill an order. A producer can also create a new order that will require either growing and producing new cannabis or sourcing from another licensed producer.

Once the production order is approved (using the new Approval Workflow in AirMed), it will cascade out all related tasks to complete the order.

For instance, a producer makes a sale to a provincial distribution warehouse for 2000 vape cartridges. The producer can create a new batch of plants as source material and then track the entire process from propagation to finished packages in master-cases loaded on a pallet to be shipped.

The entire production process can be tracked and reported on, even if the workflows to produce the vape cartridges require a third-party to manage the extraction and packaging stages.

For more information call or email us, fill out the request demo contact form or visit our Software page.

Scaling Craft Production Virtual Summit: Oct 23, 2024

The cultivation virtual summit by Grow Opportunity will investigate how to scale craft cannabis production in both an indoor and a greenhouse environment.

Join Grow Opportunity this Fall for an afternoon event taking place between 1 and 3:30 pm EDT, and hear what growers have to say about the challenges and triumphs attributed to scaling premium products. The virtual event consists of a keynote speaker, a panel discussion and Q&A opportunity with the speakers.

For more information visit: https://www.growopportunity.ca/virtual-events/focus-on-scaling-craft-production/

Report: Statista Cannabis Market Data & Analysis

The 2024 Cannabis Market Data & Analysis Report from Statista, a global data and business intelligence platform, provides an international oversight into the Cannabis market. This 72-page report offers insight into drivers, current market trends, key companies, consumer insights, and future developments in the market.

“New product innovation and a shift in attitude towards cannabis from consumers and governments have led to a growing Cannabis market. Overall, the Cannabis market realized a revenue of US$59.4 billion worldwide in 2023.”

The analysts at Statista predict that the cannabis market will grow at a CAGR of 3.01% between 2024 and 2029. “Particularly strong growth is expected in upper-middle-income countries, due to the growing trend of changes in cannabis legislation and the corresponding expansion of supporting infrastructure.”

Statista reports, “Together, the Recreational and Medical Cannabis segments account for 51% of the total global revenue, due to the major sales of cannabis for recreational and medical-use in Canada and the United States.”

Statista is a global data and business intelligence platform with an extensive collection of statistics, reports, and insights on over 80,000 topics from 22,500 sources in 170 industries. Established in Germany in 2007, Statista operates in 13 locations worldwide and employs around 1,100 professionals.

For more information about this report visit: https://www.statista.com/study/119812/cannabis-market-data-and-analysis/