AirMed Supports Direct Delivery

What is Direct Delivery?

Direct delivery programs let licensed producers sell their products directly to retailers, which can eliminate warehousing. In British Columbia, the standard practice is for LPs to send cannabis to the BC Liquor Distribution Branch’s (LDB) warehouse. Dispensaries must then choose the products they wish to buy from the LDB product list.

For retailers, the disadvantages include limiting choices to what’s available in the warehouse and typically requiring a minimum order amount. This process also does not allow retailers to select products based on freshness.

For LPs, there is no assurance that the cannabis sent to the warehouse will be ordered within its shelf life. Yet each time a product is shipped, the production facility must use a pre-paid excise stamp. As a result, LPs spend the price of the excise stamp without a guarantee of sale. The possibility exists for the cost of producing and shipping the product to be thrown away, plus there’s the extra work involved in reclaiming the excise tax.

Direct delivery lets LPs register and list products for sale through a provincial direct-to-retailer program. Dispensaries can choose products from an individual LP and arrange for delivery directly from production facility to storefront. The shipment still requires an excise stamp and provincial fees, but the sale to the retailer has already been made, which covers those costs.

The benefits of direct delivery include:

- Giving retailers greater choice when ordering plus no minimum sales and potentially shorter delivery times

- Supplying dispensaries and consumers with fresher product

- Letting LPs cultivate-to-order and preventing products from expiring in warehouses

- Removing speculative costs of excise stamps for LPs and ensuring up-front revenue to LPs

- Helping small-scale producers be more competitive in the marketplace by creating opportunities for brand marketing and promoting better customer service to retailers

How AirMed Supports Direct Delivery

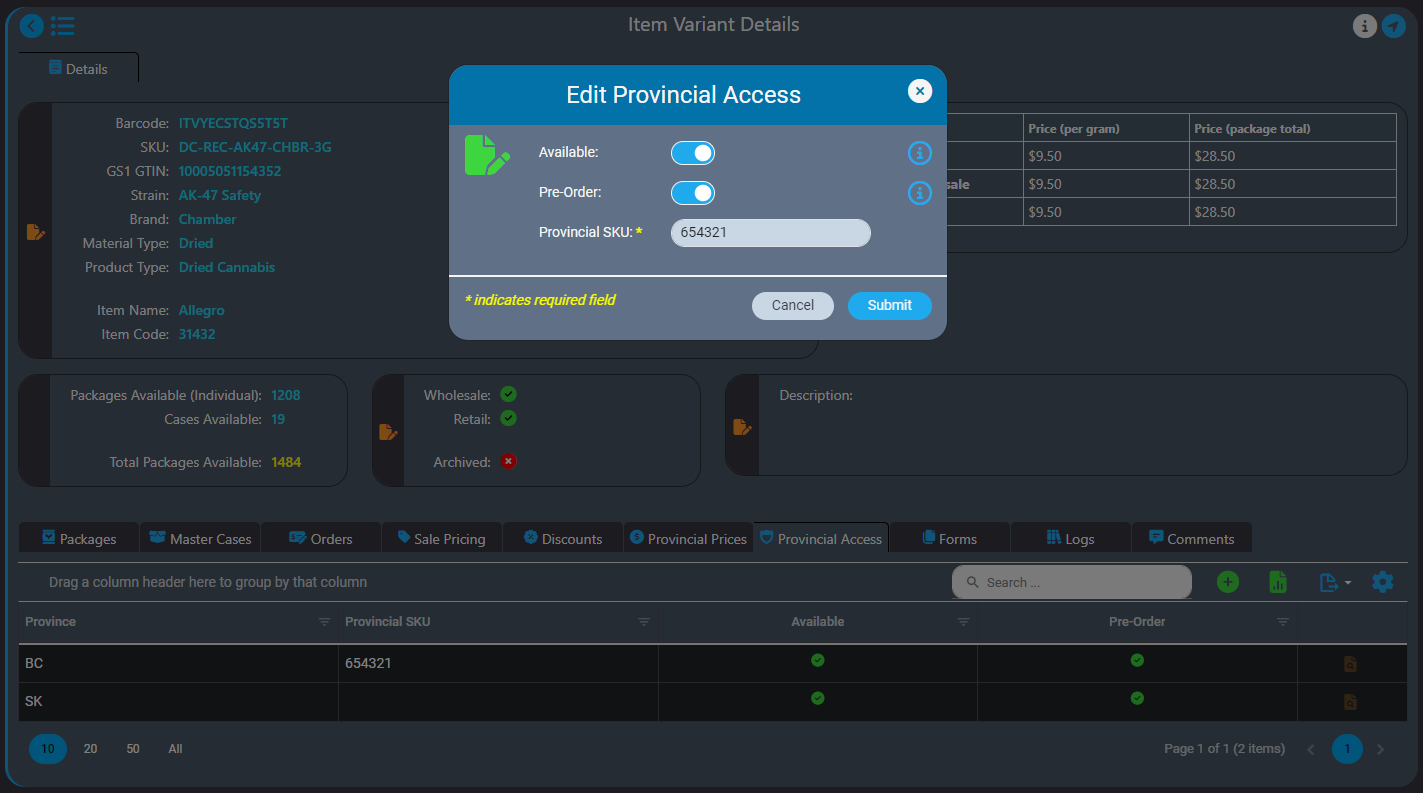

AirMed Direct Delivery offers a streamlined service that enables licensed retail stores to bypass provincial warehouses and order products directly from licensed producers who use AirMed in provinces where this is permitted, currently British Columbia and Saskatchewan.

Our built-in workflows that support direct-delivery simplify your processes making it easier for you to work with your retail partners.

WordPress Plugin for Retailer Registration

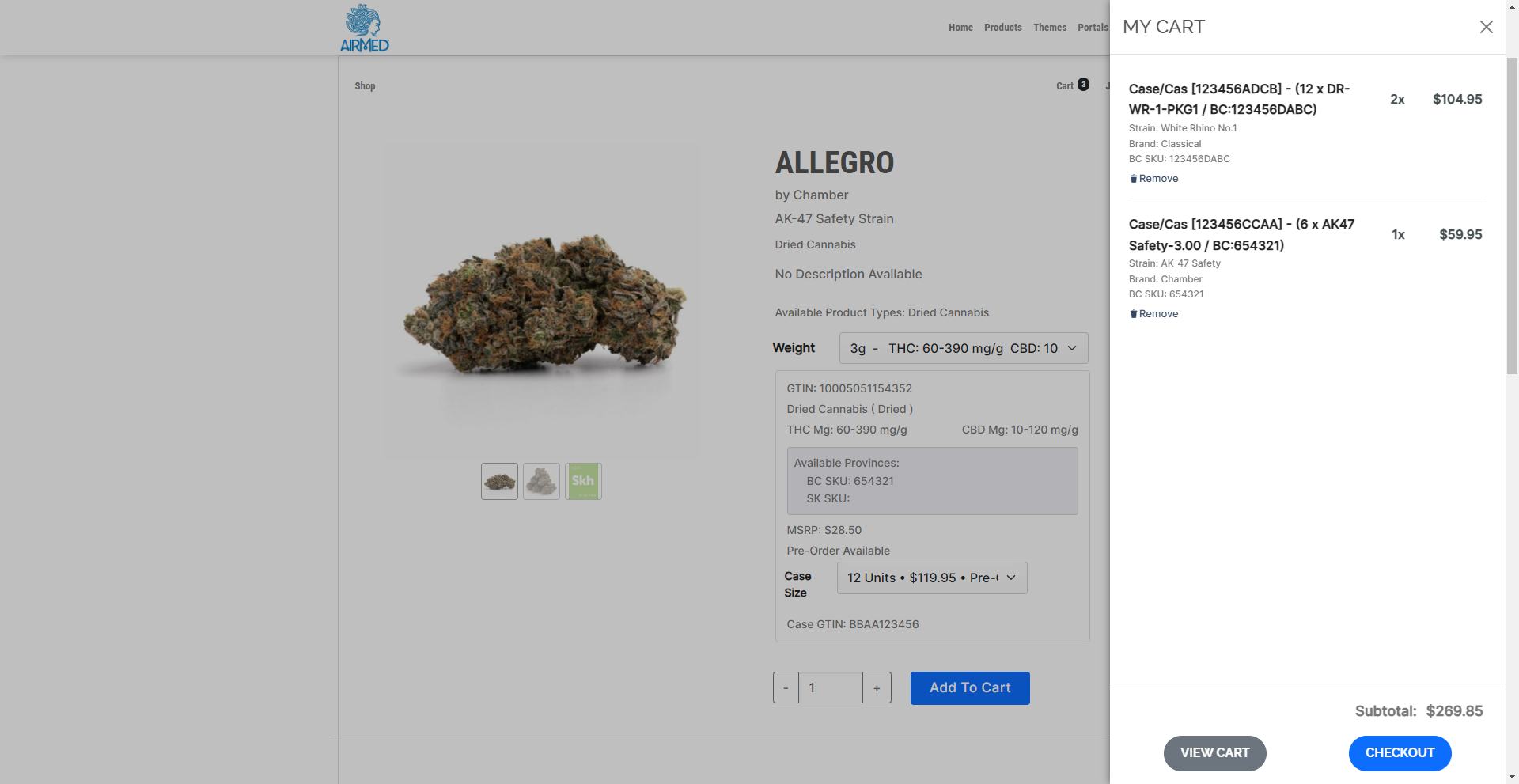

A proprietary WordPress plugin and API provide fast and easy integration of your AirMed database with an online store on your website. This lets you offer your products directly to licensed retail outlets complete with a catalog and shopping cart. Retailers can register and get approval from licensed producers through the WordPress plugin. Approved retailers gain access to a product catalogue and order cases of finished packages.

Pricing and Orders

AirMed supports different pricing structures for various provinces for both individual packages and bulk cases. AirMed also allows pre-ordering of out-of-stock products, enabling producers to manufacture based on incoming orders.

Order Fulfillment

Once an order is placed, it is automatically processed in AirMed. Producers can fulfill orders, manage payments, and ship products directly to retail stores.

Provincial Support

Direct delivery is designed to comply with current provincial regulations and can adapt to include new provinces as regulations change. You can even set up direct-delivery product availability for provinces that may elect to allow direct delivery in the future.

Our solution is ideal for those looking to streamline their supply chain and enhance their ordering process in the cannabis retail industry.

Efficiency: Retail stores can directly access products from producers who use AirMed, reducing the dependency on provincial warehouses and potentially shortening delivery times.

Flexibility: Producers can manage their inventory and production schedules more effectively through pre-orders, and AirMed manages creating product cases in varying sizes with associated case pricing for each product type and province.

Scalability: Our system can expand to include additional provinces as they permit direct delivery.

To see all the ways AirMed supports direct delivery, book a free demo by using the Request Demo button at the top of the page.

For more information on direct delivery in British Columbia, visit: https://www.bcldbcannabisupdates.com/LDBDirectDeliveryProgram

For more information on cannabis laws in Saskatchewan, visit: https://www.slga.com/cannabis

To read an article about direct delivery on the Stratcann website visit: https://stratcann.com/insight/bcs-

annabis-direct-delivery-program-is-growing-but-fees-still-too-high/c

Selling internationally? You need GS1 and GTIN!

GTIN or Global Trade Item Number is a standard from the GS1 (Global Standards) organization. GTIN consists of unique codes that identify manufacturers and their products using barcodes. When scanned by an electronic reader, the GTIN barcode provides a code that is related to a specific manufacturer and a specific product from that manufacturer.

In North American, the UPC (Universal Product Code) is an existing form of the GTIN. In Europe, EAN-13 is the GTIN standard.

The GTIN system lets you and your products be identified across the globe. If you hope to sell in certain parts of the world, such as Europe, you will need to use GS1 standards and GTIN codes. Once you have signed up with your regional GS1 office, you will be issued a series of unique codes to use on your product packaging.

Fully supporting GS1, AirMed prints your GTIN barcodes directly from the database. Our master case processing lets you use multi-level barcoding for several layers of packaging or stock-keeping units (SKU). For example, one case could contain a dozen smaller cartons. Each of those cartons could contain a dozen retail-ready individual packages. All of those packaging layers can have its own barcode to meet the retail standards of the region where it will eventually be sold.

AirMed helps you meet your barcoding and packaging standards whether selling to a provincial warehouse or shipping internationally. AirMed even lets you apply pricing at the package or the master case SKU, and custom pricing can be set for specific SKUs by customer.

For more information on GS1 standards and GTIN barcoding, visit: https://gs1ca.org/

If you’d like to discuss your specific needs, please give us a call at 1-877-313-2442 or click the Request Demo button at the top of the page to start the ball rolling.

Data collection made easy with AirMed e-form designer

For many compliance-based businesses, forms are unavoidable. Even with the most comprehensive software, forms are sometimes necessary for collection and verification of data.

While many software vendors offer electronic form functionality, in most cases the information contained in those forms is not stored in the database. This means relying on PDFs or printed documents to access the data contained in the form.

Our built-in form designer lets you create custom electronic forms that integrate with AirMed’s system data-sources. All fields in electronic forms created using the form designer can be stored in the AirMed database. There is no need to refer to physical documents or PDFs.

Using AirMed, you can automate workflows using custom e-forms to prevent the need for paper-based documentation. Forms can be linked to processes such as plant scouting, nutrient checks, room sanitation, and shop floor data collection. Using our form designer, you can employ drop-down picklists, date & time, checkboxes, radio groups, custom fields and more. AirMed lets you apply auto-complete, file upload, hidden input and electronic signatures to your forms.

All the data is electronically accessible and even reportable.

Form data collection doesn’t get any easier than that.

For more information visit our AirMed 5 page.

Workforce Management in AirMed 5

AirMed simplifies compliance by tracking and logging every action and ensures audit readiness with reports and analytics.

Employees only have access to functions and data that relates to their job responsibilities. System Administrators can only access data through approved computers utilizing a VPN connection.

And AirMed offers licensing by facility size rather than by individual user to encourage producers to configure individual accounts for every worker.

Our system improves quality management by allowing producers to identify gaps in employee knowledge and skills.

To see for yourself what AirMed can do, click the Request Demo button at the top of the page.

For more information visit our Software page.

Implementing AirMed in Your Facility

As a cloud-based platform, AirMed does not require expensive dedicated hardware to operate. Producers are free to use any computing device that supports a web browser. As a result, set up consists mainly of configuring the software to meet your needs. The rest of the time involves learning to use the system and getting your employees up and running.

How AirMed is implemented within your organization depends on the areas of the software you’ll be using. The first step in any software implementation is a needs assessment to help identify exactly how the software will be used. Understanding the capabilities of AirMed and how it can work with your processes is one of the keys to successful implementation. Your AirMed implementation specialist will work with you to perform an assessment of your needs to determine which areas of the software should be configured.

We provide an implementation guide and a production checklist that you can go through with your AirMed Implementation Specialist. Together, you’ll review the functionality in AirMed and determine which areas and functions are needed for your business operations. AirMed includes the ability to disable navigation menus for areas that you won’t be utilizing to provide a streamlined interface for your workers.

When you have completed your assessment and training, the next step is to configure your Live Production environment. After you’ve set up and tested your system, it’s time to train other users (your workers) to use AirMed.

Once users have usernames and passwords, they can access the training resources in the AirMed Learn environment. Workers can take additional training at a later date to develop skills for different areas of the system — in fact, anyone with access to AirMed can use the Learn environment at any time to practice new workflows or refresh their knowledge. When employees have completed training, you can give them access to the system, so they can get to work.

With AirMed you can implement only the functionality you need right now. For example, you can start by implementing the AirMed Grow module, then when you expand your operation, you add modules that meet your current needs for performing extractions, packaging for provincial sales, selling to medical patients or whatever your business entails.

Working with your implementation specialist will help you see all the benefits of using AirMed and ensure that you are getting the most from our software.

For more information on how AirMed helps specific types of businesses, visit our Customers page or our Frequently Asked Questions page.

Ready to learn more about AirMed? Click the Request Demo button or call 1-877-313-2442.

AirMed and FDA CFR 21

We are sometimes asked if AirMed meets FDA standards. First, please be aware that the FDA is a department of the US government. The specific portion of FDA regulations relevant to software such as AirMed is part CFR 21. As it is an American standard, Health Canada does not require CFR Part 21 compliance as part of the Cannabis Act Regulations. And while AirMed was designed for the Canadian cannabis industry and to comply with Health Canada regulations, AirMed does conform to CFR Part 21 with respect to electronic record keeping, audit trails, and electronic signatures.

Many agencies throughout the world are responsible for issuing and enforcing regulations that affect businesses. The regulations affecting software such as AirMed are typically those related to records management compliance. And while there are many regulatory agencies involved in records management, for the most part the regulations themselves are similar from country to country and agency to agency. The purpose of them, in general, is to ensure the security, confidentiality and authentication of electronic records.

The U.S. FDA regulates food, drugs, medical devices, biologics, animal feed and drugs, cosmetics and radiation-emitting products such as cell phones for the U.S.A. The FDA’s rules for manufacturing and distribution are designed to protect consumers and promote public health. In the U.S. Code of Federal Regulations (CFR), Title 21 deals with Food & Drugs. Until recently, the regulations in this title required paper records with handwritten signatures.

Back in 1997, part 11 of 21 CFR was enacted to cover the use of electronic records and electronic signatures. Commonly known as 21 CFR 11, this part defines the criteria “under which the agency considers electronic records, electronic signatures, and handwritten signatures executed to electronic records to be trustworthy, reliable, and generally equivalent to paper records and handwritten signatures executed on paper.”

Essentially, the concerns about using electronic records are that records may be lost in a system crash, the data may become corrupt or modifications may be made without proper authorization. In addition, since printed documents with hand-written signatures are recognized as legally binding on the signators, the agencies are looking for ways to make electronic records similarly binding on their owners. The regulations have been proposed to ensure that whenever an organization replaces printed documents with electronic data, there are checks and balances in place to ensure integrity of the electronic records so that they can be legally equivalent to printed records.

AirMed has a range of features that satisfy standards for security, authentication, validation and auditing as outlined in 21 CFR 11 and other regulations.

For more detailed information visit: Code of Federal Regulations (CFR) | FDA

For more information on how AirMed helps you meet compliance, visit our Compliance page or our Frequently Asked Questions page. If you’d like to discuss your specific needs, please give us a call at 1-877-313-2442 or use one of the contact forms to start the ball rolling.

FREE Seed-to-sale Software Buyer's Guide

Record keeping is an essential part of Health Canada’s compliance regulations. From the advent of legal medical marijuana in Canada, legal producers of cannabis have been required to track every seed, rooted plant, gram of waste material, final dried product, as well as interactions with customers and more. Due to the sheer volume of information, an electronic record-keeping system is the only practical way to manage the process. The software industry has responded to this need by creating seed-to-sale management software systems designed to help producers track their operations and report to Health Canada to meet compliance.

To help you through the process of purchasing seed-to-sale software in the Canadian Cannabis marketplace, we’ve produced a 20-page guide that answers the following questions:

- What is a seed-to-sale software solution and why do I need one?

- How do I choose one software platform over another?

- What should I be looking for in the software?

- How does the software fit into my business?

- How is my data stored and secured?

- What happens if regulations change?

To download this guide courtesy of AirMed, please visit the following page and complete the form. Once you submit the form, you’ll be able to download the guide.

Cannabis Prospect Interviews AirMed CEO Justin Hearn

Cannabis Prospect interviewed AirMed Canada Systems Inc. president and CEO Justin Hearn for an article published on the magazine’s website on May 15, 2023.

In the feature, titled “How AirMed is Helping Canadian Cannabis Producers Cultivate Success,” Hearn discussed the ways AirMed software is adapting to the changing market conditions.

“Our new AirMed 5 version focuses on streamlining data entry and improving quality management and profitability for cannabis operations… We’ve modelled the workflows on commonly accepted manufacturing procedures and terminology incorporating task-based work orders that let organizations precisely track the costs incurred for running their facilities.”

Hearn goes on to say, “AirMed is adapting its software to support increased insight as well as new strategies to boost efficiency, reduce costs, and improve the bottom line.”

Read the full interview here: https://cannabisproonline.com/article/

Download a PDF of this article: Cannabis Prospect Justin Hearn Interview PDF

For more information on AirMed 5, visit: https://airmedcloud.com/intro-airmed-5/

The AirMed Two-way API

AirMed 5 will include a two-way application programming interface (API) for custom system integrations with room sensors, accounting systems, QMS systems, ERP systems, point-of-sale (POS), enterprise resource planning (ERP) and environmental monitoring.

Environmental Monitoring Integration

Temperature, humidity, CO2, and hundreds of other potential conditions can be logged during the grow cycle to control processes and productivity.

We’re adding integration for environmental sensors and nutrient monitoring with support for different sensor companies based on customer requirements.

Lighting schedules, HVAC settings, nutrient mixes, and foliar applications are tracked to improve current and future outputs.

ERP Integration

We are currently working on support for Microsoft Dynamics, and additional ERP systems will be added on a per-customer request basis.

For more information on these new features or to book a demo of AirMed to see them for yourself, click the Request Demo button at the top of the page or use any of the contact forms.

In the meantime visit our Software page.

Templates & Automation in AirMed5

Smart Input Fields

AirMed 5 includes a number of new automation features and templates to help you work more efficiently.

Plan Templates

Plan templates are designed to help create formulas for production. For instance, after completing the cultivation, drying and packaging of a new batch, a Batch Plan template can be created to map out the time in each grow phase based on the values from the existing plan. In addition, the average number of grams per plant can be automatically calculated based on the batch harvest statistics. Once a batch plan is created, it can be attached to a strain so that the next time it is propagated, the default values can be automatically set.

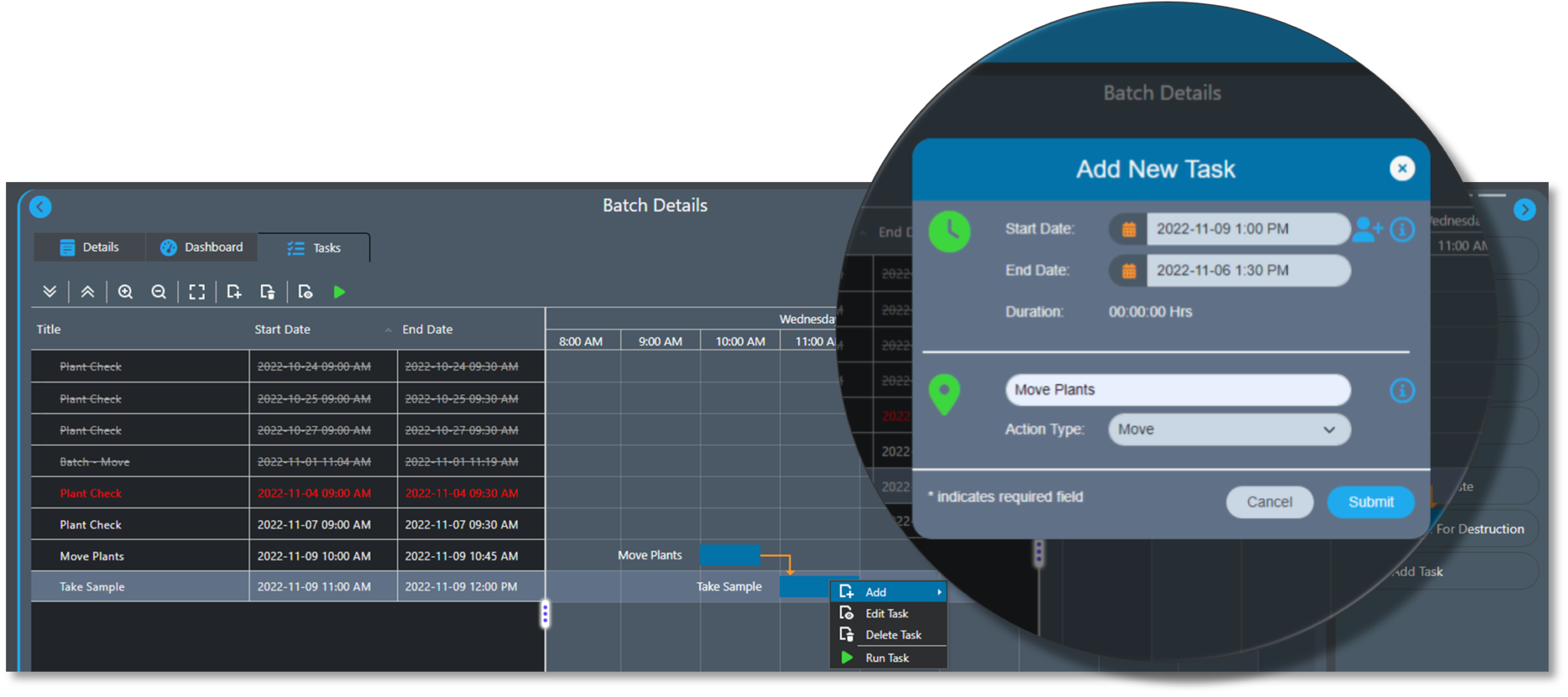

Work Order Task Templates

AirMed5 features a comprehensive task template with activities or scheduled actions available to automate a series of tasks required to complete a process. A task in AirMed is a block of time associated with an activity.

Once recorded and accumulated, a series of tasks can become a template. You can create a template for the a grow cycle or a specific process. That template can serve a work order to help manage cultivation or the manufacture of extractions, topicals and edibles.

Tasks can be assigned to different departments or users with activities cascaded across the entire production cycle. For example, if a template is associated with a strain, future propagation events will automatically schedule the tasks related to cultivation, harvesting, packaging, and more. Tasks let you capture information, compile them, and use the template as a work order to accomplish processes as efficiently as possible.

For more information on these new features or to book a demo of AirMed to see them for yourself, click the Request Demo button at the top of the page or use any of the contact forms.

In the meantime visit https://airmedcloud.com/airmed-5-intro/

Quality Management in AirMed5

Multi-level Approvals

AirMed5 includes the option to record eSignatures and lets you create an approval workflow with one or more signatures required for a given activity.

Approval workflows can include a single signature or one or more unique signatures plus optional witnesses. When an individual is tasked with electronically signing for an approval, a notification is sent through the AirMed internal messaging system. Within the message is a quick link to the location where the eSignature is required.

QMS Incident Tracking

A new incident management system lets users record incidents that deviate from normal operating protocols or that affect compliance data. Incident tracking can be used in any area of the facility including plant growth, extraction, orders and fulfillment.

Incidents can be automatically created when certain events occur, such as back-dating or undoing/editing specific data. AirMed creates a comprehensive audit trail for any alteration made to compliance data and provides auditors with a tool to examine corrections or modifications.

Escalation & Investigations

Escalation of specific types of incidents can be automated using message notifications. Users can initiate an inquiry related to an incident and have it automatically escalated to an appropriate investigator.

Investigations could be related to any incident such as employee illness or injury, hazardous spills, deviations, non-conformance, loss or theft, recalls, vender audits, crop destruction, pests, or any other incidents. AirMed manages each incident through the cycle of investigation, evaluation, resolution, corrective action, and procedures.

For more information on these new features or to book a demo of AirMed to see them for yourself, click the Request Demo button at the top of the page or use any of the contact forms.

In the meantime visit https://airmedcloud.com/airmed-5-intro/

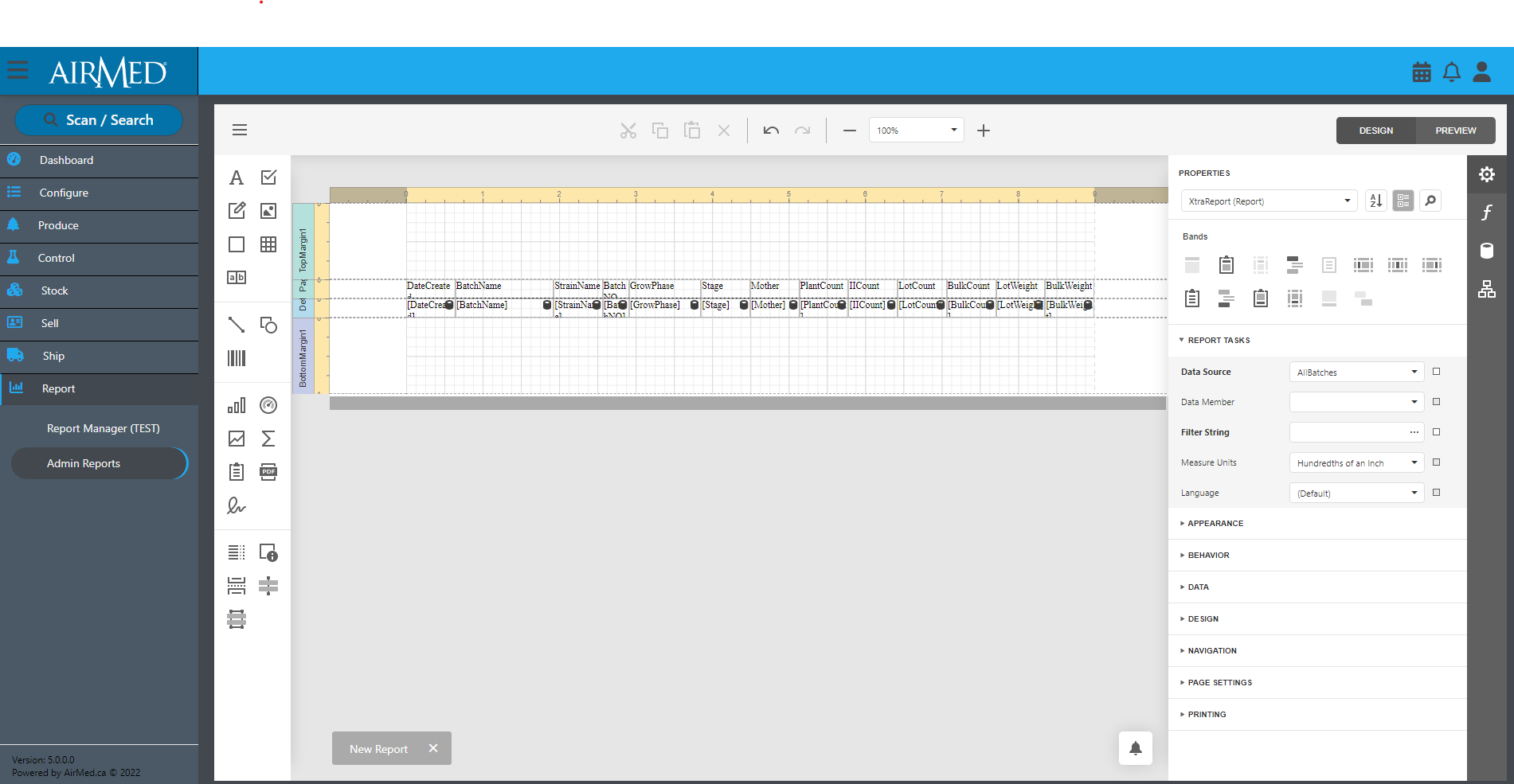

New Design Tools in AirMed5

Report and Label Designer

Leading the industry in design tools, AirMed5 includes an optional report and label designer. This powerful tool lets you design your own reports that can be accessed throughout the software.

Business Intelligence Designer

With our new optional Business Intelligence designer, customers will be able to build their own widgets and attach them to relevant areas throughout the system.

Custom Form Builder

A new form designer will let you create custom forms that access to system data-sources. Custom forms include drop-down lists, custom fields, data & time fields, electronic signature fields, checklists and more.

For more information on these new features or to book a demo of AirMed to see them for yourself, click the Request Demo button at the top of the page or use any of the contact forms.

In the meantime visit https://airmedcloud.com/airmed-5-intro/

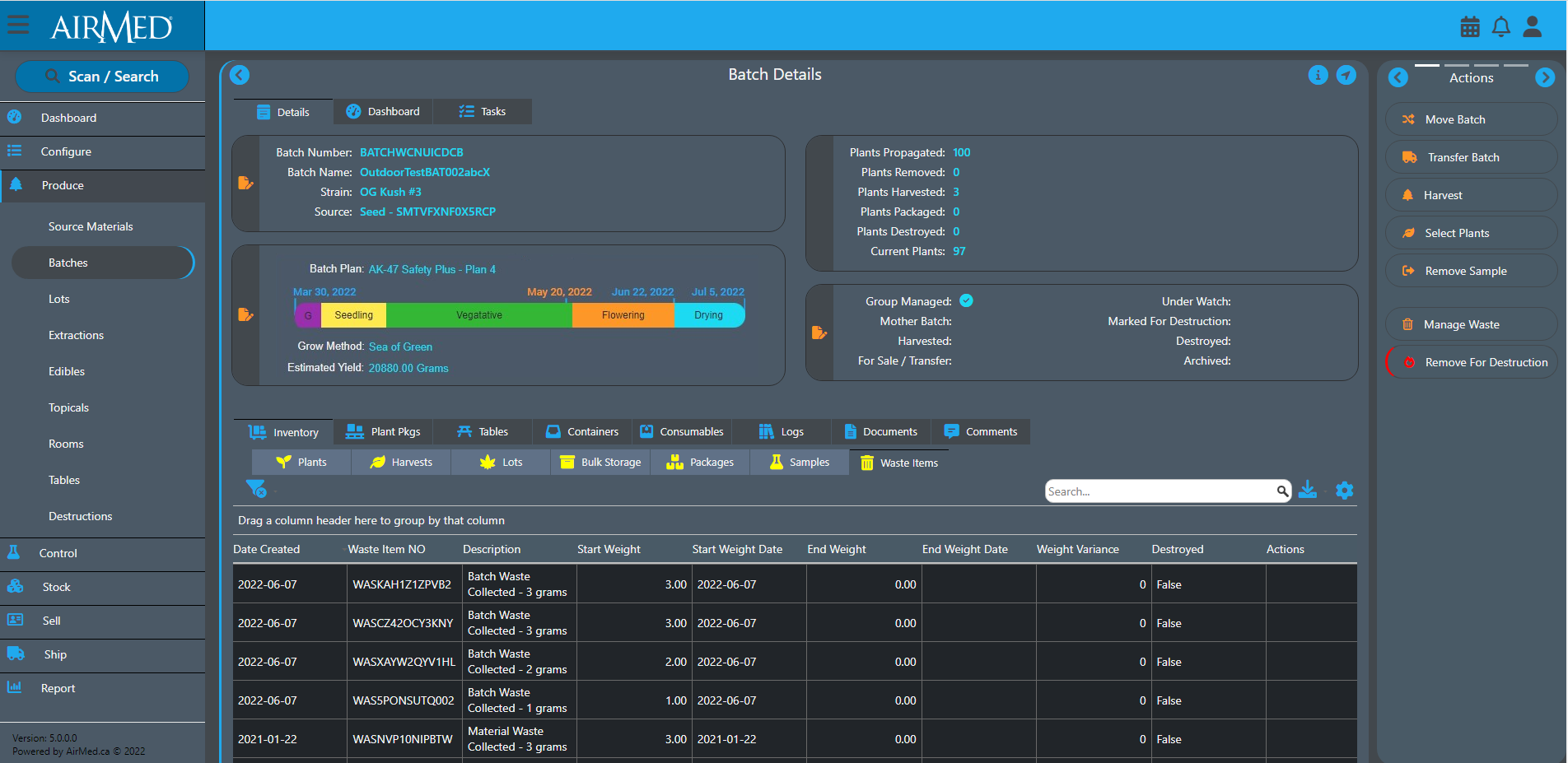

Redesigned Interface in AirMed5

AirMed is getting a completely redesigned interface. AirMed5 will offer light and dark themes for use under bright lights in work areas such as grow rooms. When using the dark theme, less light is reflected from the screen to limit oversaturation from dark text on a light background.

The new look and feel will make it easier to process the information on screen and navigation lets users see where they are in the application at a glance. Infographics are being incorporated where applicable to display more details using less screen space.

We’re minimizing the number of clicks required to complete each step in a process. The actions menu is extended with a carousel, and a new grid control offers new options for viewing, sorting, searching, and grouping data. Columns can be rearranged to match a user’s preference, and settings are saved for future sessions.

And there’s so much more.

For more information on these new features or to book a demo of AirMed to see them for yourself, click the Request Demo button at the top of the page or use any of the contact forms.

In the meantime, visit https://airmedcloud.com/airmed-5-intro/

AirMed Sales Interface

From a simple catalog of available brands to medical client registration, secure encrypted messaging, and product purchase/fulfillment, AirMed offers a complete sales solution with unmatched simplicity and extensibility.

Online Catalog

Our proprietary WordPress plugin embeds information from the AirMed database directly onto your website.

You simply install a plugin into your WordPress dashboard and add a snippet of shortcode to the page where you want your catalog to appear. The shortcode pulls product information directly from your AirMed database, complete with images, descriptions and pricing. Customers interacting with the catalog remain on your website throughout the shopping experience rather than being transferred to an embedded portal site.

To support non-WordPress platforms, an API is available for direct integration into websites, ecommerce systems, and other software systems.

Payment Processing

Online sales functionality includes a shopping cart, coupon application, and payment processing with ecommerce integration. AirMed currently supports credit card payments made through Realex by Global Payments.

Delivery Integration

AirMed can automatically create a shipment record after an order is paid and validated. Connect directly to the courier and print the resulting label to streamline the shipping process and enable a tracking URL to be linked.

And there’s so much more in AirMed to support online catalogs and sales.

To learn more about our online features and how AirMed supports medical sales, contact us to request an info sheet by using one of the contact forms or by emailing: info @ airmed.ca

To see these features for yourself, click on the Request Demo button at the top of any page.

New reports in AirMed keep pace with marketplace

AirMed has the most comprehensive reporting in any cannabis management system. To ensure that our reporting keeps pace with changes in regulations and the cannabis marketplace, we regularly update our reporting system and add new reports.

Industry analysts and market researchers agree that edibles are the future of cannabis as consumer preferences shift from away from smoking.

Seattle-based data-analytics firm Headset examined sales from the US and Canada and reported “…overall edibles sales grew by more than 20%…”

According to a different report titled Cannabis Edible Products Market Report, “The aversion to smoking is one of the main factors that has led to the significant growth of cannabis-infused edibles over the past years.”

MJ Biz Daily reported that “The outlook for edibles is considered bullish among industry executives… Industry executives said consumers around 30-45 years old especially seem to be entering the cannabis market via edibles.”

To support the addition of edibles and topicals functionality in AirMed earlier this year, we added new CTLS data reporting. We also updated the existing CTLS Full Export function to include the totals from the main CTLS reports.

The release of edibles and topicals functionality in tandem with supporting CTLS reporting lets users manage entire edible and topical inventory data in AirMed and also export data into a pre-populated CTLS monthly report using the CTLS Full Export function. This vastly improves the inventory tracking capabilities for edibles and topicals and can save users valuable time in monthly reporting.

AirMed is working hard to support consumer trends so cannabis producers and processors can meet the needs of the marketplace.

The “Cannabis Edible Products Market Report” can be found at: https://www.researchandmarkets.com/reports/5529328/cannabis-infused-edible-products-market-growth

The Headset “Cannabis Product Trends” report can be found at: https://www.headset.io/industry-reports/the-most-popular-cannabis-product-trends-in-the-us-canada

Read more from MJ Biz Daily on the edibles market here: https://mjbizdaily.com/led-by-gummies-edibles-keep-pace-with-growth-of-overall-us-marijuana-market/

To learn more about AirMed reporting visit: https://airmedcloud.com/software/#report

For a demo of AirMed’s reporting features, click the Request Demo button at the top of the page or use the contact form in the footer. You can also call us directly at 1-877-313-2442.

Quality Management and AirMed

Constantly innovating to help our clients, we have a host of features in development for our seed-to-sale software. One of the most significant improvements currently in development for AirMed is built-in Quality Management.

A Quality Management System (QMS) can help your organization mitigate regulatory risk by providing the tools you need to meet the requirements and standards for Health Canada’s Good Production Practices. But risk reduction is not the only benefit of QMS. You can also improve efficiency, provide consistent control over processes, and much more. As a result, we’re building a range of QMS features into AirMed including the following.

- Escalation and Tracking: Escalation and tracking will be available for use in any area of the facility such as plant growth incidents, extraction incidents, order and fulfillment incidents.

- Vendor Approval Process: A multi-level approval process will be supported for new vendors who supply products.

- Enhanced Received Product Management: New features are being added for received product quarantine, testing and release for use. The new functionality will support having certain received products undergo QA to ensure they match specifications. QA results can be uploaded to support this workflow.

- SOP Management: Standard Operating Procedures (SOP) are critical to QMS, and we will be adding SOP management for current and historical SOPs with auto-versioning to track changes in procedures.

- Electronic Signatures: Electronic signatures will be available for workflows such as destruction, sanitation, and processes that need approval from a responsible person in charge.

- Case Management for Plant Issues: With new support for both SMS and MMS notifications, a grow tech concerned about a plant will be able to send a photo to the head grower for instant review.

We’re working hard to meet shifting customer needs and market demands in the Canadian cannabis industry, turning your feedback into important product advancements. AirMed seed-to-sale business solutions go beyond compliance to help licensed producers cultivate success.

If you’d like to read about Canada’s Good Production Practices for Cannabis, visit https://www.canada.ca/en/health-canada/services/cannabis-regulations-licensed-producers/good-production-practices-guide.html

For more information about AirMed visit our software page.

If you have specific questions or would like a free demo of AirMed, please contact an AirMed sales representative by filling out one of our contact forms or calling 1-877-313-2442.

Software Validation for Cannabis Processors

One of the challenges for cannabis processers is that regulations require them to validate their extraction practices. In many cases, those practices involve the use of software. Therefore, any software used in relation to production must be validated along with the practices.

As tracking production reliability is an important part of meeting compliance, most tracking involves the use of software.

Software vendors are responsible for ensuring the software they sell works as described. But, validating that software is the responsibility of the processor. Why? Because every organization operates differently, and validation must be done in relation to actual production practices.

If you are using AirMed as your system-of-record, you will need to validate our software as it is used in your facility.

AirMed helps you through the validation process by providing test scripts that can be used to validate each task in the workflows that relate to extraction processes. These test scripts show what the software was designed to do, how the software should be used for that specific task and what the end result should be.

We can provide you with a validation report outlining how we meet software vendor compliance. Our validation report details how our software complies with security, privacy and accessibility requirements. AirMed software has been designed to not only meet compliance with Canada’s Cannabis Act but also to support and comply with Federal and Provincial privacy legislation and regulations (PIPEDA, PIPA, PHIPA, PHIA). AirMed also meets the standards outlined in the US FDA 21 CFR Part 11, which many other specifications are based on.

Our internal procedures have been through an external vendor audit for the pharmaceutical industry and passed with no observations.

If you’d like to learn more about good production practices for cannabis in Canada, the Government of Canada has published GPP guidance information here: https://www.canada.ca/en/health-canada/services/cannabis-regulations-licensed-producers/good-production-practices-guide/guidance-document.html

For more information on how AirMed helps you meet compliance, visit our Compliance page or our Frequently Asked Questions page. If you’d like to discuss your specific needs, please give us a call at 1-877-313-2442 or use one of the contact forms to start the ball rolling.

Managing Extracts, Edibles & Topicals in AirMed

For those wishing to process extracts, edibles and topicals, AirMed offers comprehensive features dedicated to these classes of cannabis.

Extracts, edibles and topicals are categorized as special classes of cannabis due to the unique public health and safety risks they present. As a result, these cannabis products have specific requirements pertaining to their formulation, production and composition.

Health Canada licensed processors have a broad base of data management needs to maintain compliance and accurately complete the monthly CTLS report. AirMed has developed a full range of functionality to meet those needs.

As with all elements of our system, comprehensive tracking and reporting is available. AirMed tracks and reports on every aspect of processing with specific fields for managing extracts, edibles, and topicals as well as their materials and lots.

Access to the AirMed software functionality that manages these cannabis classes is controlled on a user-by-user basis. Workforce management in our software utilizes configurable departments and job roles to control which workflows workers are authorized to use. You determine who is given rights to these production areas based on the needs of assigned job roles.

The AirMed cannabis record management system has separate production sections for extracts, edibles and topicals with workflows designed specifically to meet their requirements

AirMed offers workflows for storing extractions after processing for further processing or for blending with other materials and more. Weights are tracked to five decimal places for precision and reporting.

Packaged products can be sold individually to medical clients or as packaged products to recreational users.

Packaging features in AirMed include the ability to create discrete units such as edible gummies or gel caps, which can be recorded individually in groups or as bulk packages.

Packaging of discrete units can be one discrete unit in a package, multiple discrete units in a package, or bulk discrete units in a bulk package for either storage or to sell as bulk units to another licensed producer.

All labels are produced and created from within AirMed and can be customized to your needs.

To facilitate the sale of products to provincial warehouses, AirMed offers GS1 barcoding and configuration for tracking product cases and master cases.

Inventory management in AirMed is designed to provide a centralized view of your current stock levels of all products to help control costs, manage planning, and forecast with extensive reporting tools.

Shipping is easy with built-in functionality and integration with Purolator services.

Each field related to extractions, packaging, discrete units, samples, and order fulfilment is automatically included by AirMed in Health Canada CTLS and CRA monthly reporting.

With more stringent requirements for these cannabis classes comes a greater need for control and risk mitigation. Quality management (QMS) helps you provide the finest you can offer while reducing risks.

To give our clients the best chance of cultivating success, we’re building a range of QMS features into AirMed to support Good Production Practices (GPP) and a Preventive Control Program (PCP).

No other cannabis record management system offers the breadth of functionality, ease of use, and comprehensive features to cover all classes of cannabis and help you control cost.

- Dried cannabis

- Fresh cannabis

- Cannabis plants

- Cannabis plant seeds

- Edible cannabis

- Cannabis extracts

- Cannabis topicals

To read about the Health Canada requirements related to processing cannabis extractions, edibles and topicals, read the guidelines at: Government of Canada.

For more information about the features in AirMed, visit our Software page.

To schedule a free demo of AirMed, please use the button at the top of the screen or fill out any of the contact forms.

And if you’d like to learn more about any of the features mentioned, give us a call at 1-877-313-2442.

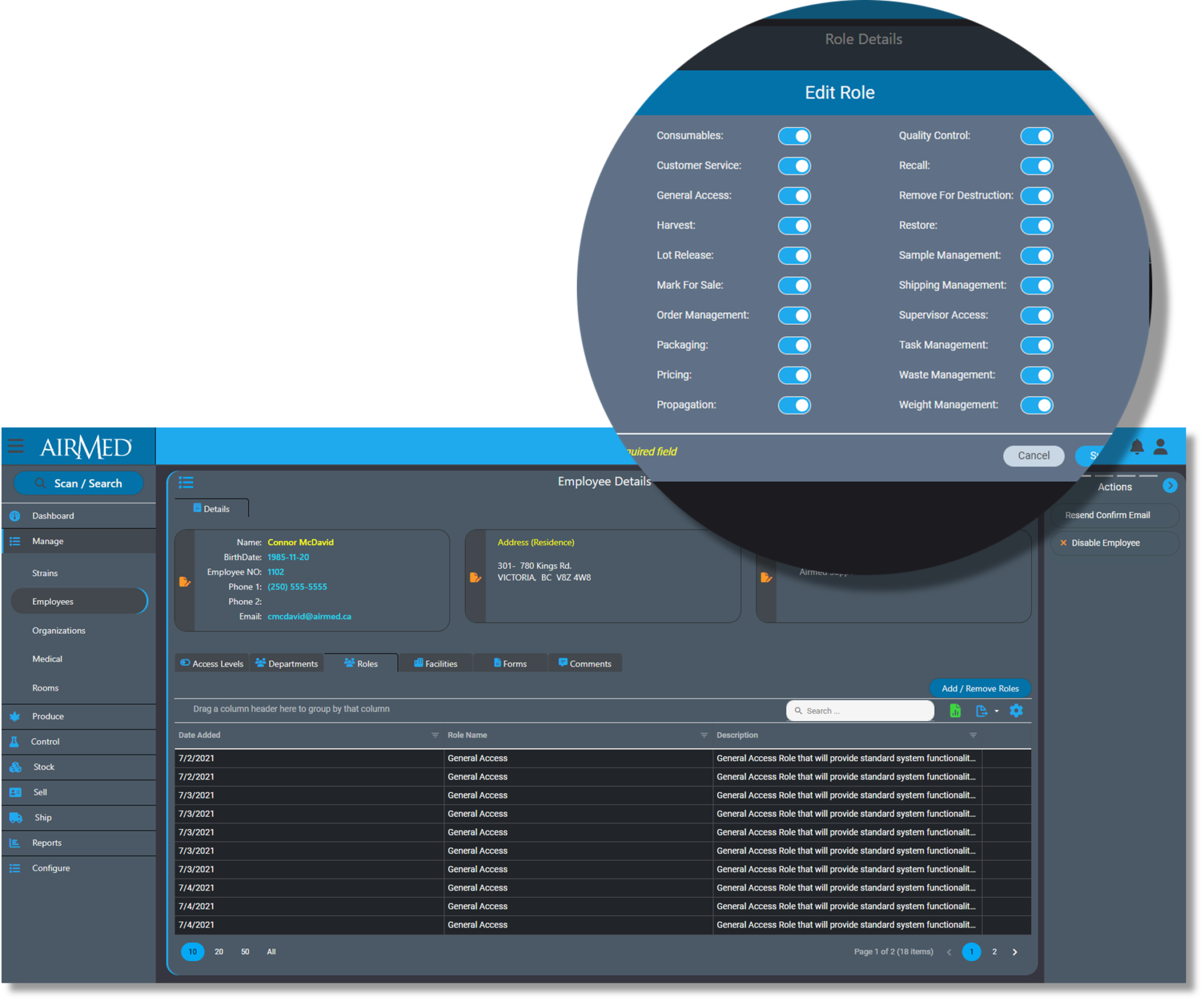

Role-based Management in AirMed

Role-based management in AirMed helps control employee access to the software system.

Actions within AirMed are linked to roles. When you assign a role to an employee, you allow access to those actions.

Employees can be assigned to the roles that correspond to the requirements of their jobs. Employees not assigned to specific roles are prevented from accessing the associated workflows.

For example, if a staff member is new and working in cultivation, you can create a role that only provides access to certain actions in the Source Material, Batch, and Lot Details screens. All other action items will not be visible. This lets you restrict access to parts of the system, based on a user’s job function within your organization.

AirMed has several roles defined by default, but you can create as many roles as required. You can also edit or rename existing roles to match your organization’s workflows. Within each role you can specify which actions are associated.

For more information about how roles can help you manage employee access, contact us today by using one of the contact forms or by calling 1-877-313-2442.

For more information on how AirMed helps you business, visit our Software page or our Frequently Asked Questions page. If you’d like to discuss your specific needs, please give us a call at 1-877-313-2442 or use one of the contact forms to start the ball rolling.

AirMed still 100% Canadian owned

As US corporations buy up seed-to-sale software companies in Canada, AirMed is still 100% Canadian owned.

AirMed was created in 2014 to help Canadian licensed producers meet compliance at all levels of government. Continuously innovating since then, we believe that building a culture of quality is an important part of our customers’ success. This commitment to quality is why a growing list of cultivators, nurseries, processors, manufacturers, and dispensaries use AirMed.

We rely on industry requirements and customer feedback to drive AirMed development, rather than investor pressure. We encourage our users to tell us what matters most to them in a cannabis management system. This feedback helps guide us in adapting AirMed to improve efficiency, productivity and user experience.

Our goal is to provide a responsive solution that not only meets customer needs but anticipates them, regardless of the size or focus of your cannabis business. That has been our driving force for nearly eight years.

Contact AirMed for a demo today to see what homegrown can do for you. Call us at (877) 313-2442 or use the contact form in the footer of this page.

For more information about AirMed, visit our About page or our Frequently Asked Questions page. If you’d like to have a conversation about AirMed, please give us a call at 1-877-313-2442 or use one of the contact forms to start the ball rolling.