Our new Production Orders features will offer the ability to synchronize AirMed more easily with external enterprise resource planning (ERP) systems such as NetSuite or Microsoft Business Central.

When combined with tasks and approvals, this provides a high level of automation and ensures that product that is created meets market demand.

Internal Production Orders

Production Orders are essentially a wrapper for activities related to producing material such as cannabis, extractions, packages, topicals, or edibles.

Internal Production Orders are used to plan for production over a specified period of time. For instance, if producers are involved in cultivation, they can create internal production orders to produce new batches, harvest and dry them, and produce bulk products for sale or for additional processing.

Once a production order is created, it can optionally cascade out all the tasks related to the item being produced, even if some of the production requires routing to external organizations and suppliers.

Internal production orders can be used to plan production for any period of time. Multiple internal production orders can cover an entire year for a producer.

External Production Orders

External production orders are based on a sale to another organization, such as a provincial government distribution warehouse. An external production order would typically be tied to a purchase order from an external organization.

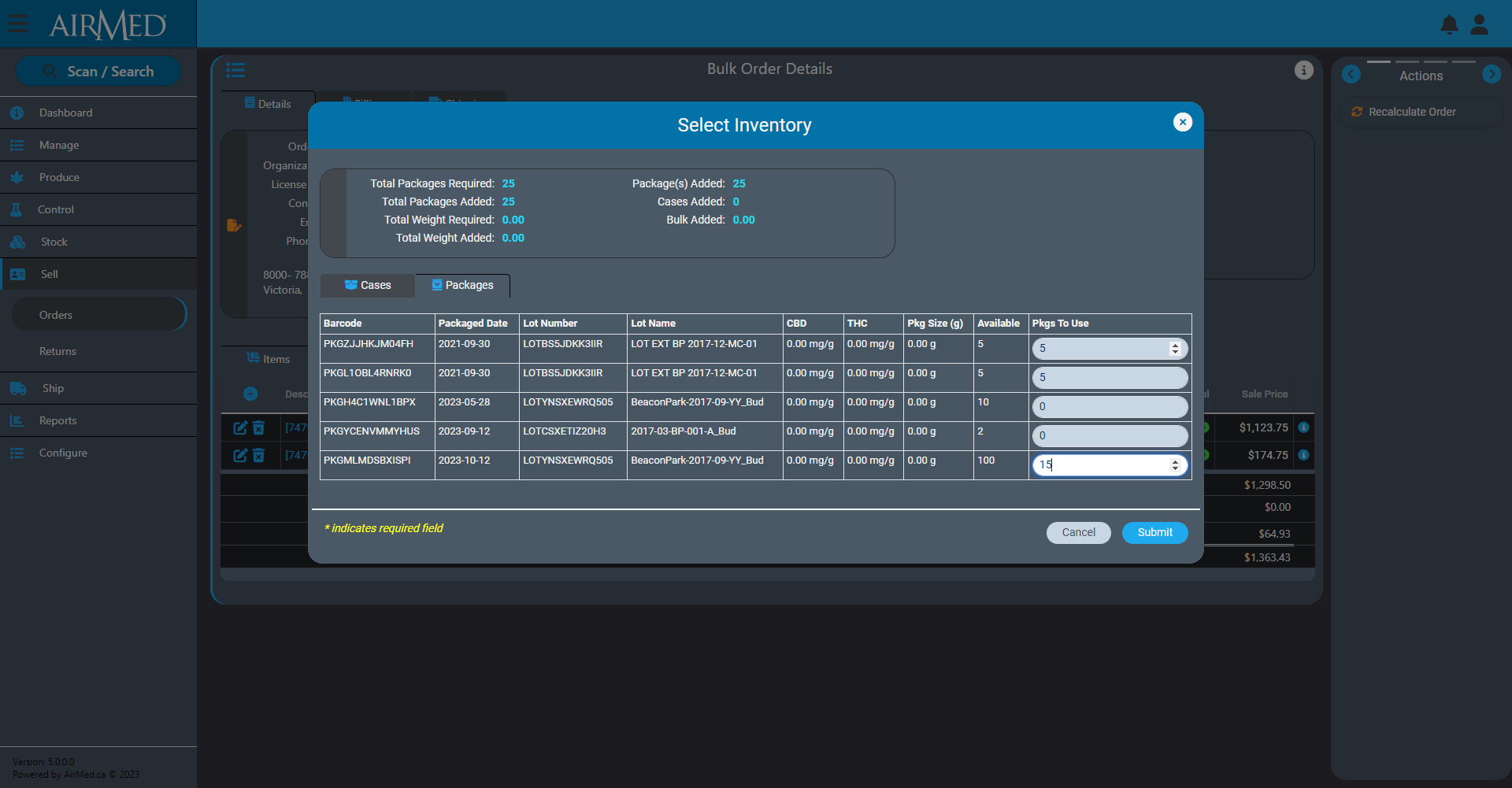

Using this feature, a producer will be able to see if there is existing inventory to fill an order. A producer can also create a new order that will require either growing and producing new cannabis or sourcing from another licensed producer.

Once the production order is approved (using the new Approval Workflow in AirMed), it will cascade out all related tasks to complete the order.

For instance, a producer makes a sale to a provincial distribution warehouse for 2000 vape cartridges. The producer can create a new batch of plants as source material and then track the entire process from propagation to finished packages in master-cases loaded on a pallet to be shipped.

The entire production process can be tracked and reported on, even if the workflows to produce the vape cartridges require a third-party to manage the extraction and packaging stages.

For more information call or email us, fill out the request demo contact form or visit our Software page.